Abstract

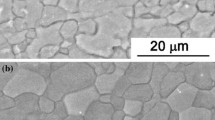

The paper presents the results of a study of the effect of the texture of a magnesium specimen on the mechanical properties of its plates and foils. Three cylindrical specimens with different columnar structure orientation were used for the experiments. The deformation was carried out in two steps at room temperature. First, long magnesium plates 1 mm thick (true deformation e ~ 3.9) were produced by lateral extrusion. These plates were then deformed by rolling to obtain foils, 120 μm thick (e ~ 6.0) and 10 μm thick (e ~ 7.5). It was seen that the sharpness of the basal texture and mechanical properties depend on the orientation of the initial samples. It has been shown that the deformation leads to a significant grain refinement: from several millimeters to several microns. This is due to the simultaneous development of slip, twinning, and dynamic recrystallization processes.

Similar content being viewed by others

REFERENCES

G. V. Raynor, The Physical Metallurgy of Magnesium and Its Alloys (Pergamon Press, London, 1959).

B. L. Mordike and T. Ebert, “Magnesium: Properties—applications—potential,” Mater. Sci. Eng., A 302, 37–45 (2001).

D. R. Nugmanov, O. Sh. Sitdikov, and M. V. Markushev, “Structure of magnesium alloy MA14 after multistep isothermal forging and subsequent isothermal rolling,” Phys. Met. Metallogr. 116, 993–1001 (2015).

A. A. Bryukhanov, M. Rodman, N. A. Volchok, P. P. Stoyanov, M. Schaper, and H. Klose, “Mechanical properties of AZ31 alloy sheets deformed by low-cycle reverse bending,” Phys. Met. Metallogr. 115, 98–105 (2014).

T. Obara, H. Yoshinga, and S. Morozumi, “{1122}〈1123〉 slip system in magnesium,” Acta Metall. 21, 845–853 (1973).

J. Kioke, T. Koboyashi, T. Mukai, H. Watanabe, M. Suzuki, K. Maruyama, and K. Higashi, “The activity of non-basal slip systems and dynamic recovery at room temperature in fine-grained AZ31B magnesium alloys,” Acta Mater. 51, 2055–2065 (2003).

J. A. Valle del, F. Carreno, and O. A. Ruano, “Influence of texture and grain size on work hardening and ductiliry in magnesium-based alloys processed by ECAP and rolling,” Acta Mater. 54, 4247–4259 (2006).

T. G. Langdon, “Twenty-five years of ultrafine-grained materials: Achieving exceptional properties through grain refinement,” Acta Mater. 61, 7035–7059 (2013).

A. Yamashita, Z. Horita, and T. G. Langdon, “Improving the mechanical properties of magnesium and magnesium alloy through severe plastic deformation,” Mater. Sci. Eng., A. 300, 142–147 (2001).

S. Suwas, G. Gottstein, and R. Kumar, “Evolution of crystallographic texture during equal channel angular extrusion (ECAE) and its effects on secondary processing of magnesium,” Mater. Sci. Eng., A 471, 1–14 (2007).

S. Biswas, D. S. Singh, and S. Suwas, “Room-temperature equal channel angular extrusion of pure magnesium,” Acta Mater. 58, 3247–3261 (2010).

A. Yu. Volkov and I. V. Klukin, “Improving the mechanical properties of pure magnesium through cold hydrostatic extrusion and low-temperature anneling,” Mater. Sci. Eng., A 627, 56–60 (2015).

Mechanical Behavior of Materials under Pressure, Ed. by H. Pugh (Van Nostrand, Amsterdam, 1970; Mir, Moscow, 1973).

I. C. Choi, D. H. Lee, B. Ahn, K. Durst, M. Kawasaki, T. G. Langdon, and J. Jang, “Enhancement of strain rate sensitivity and shear yield strength of a magnesium alloy processed by high pressure torsion,” Scr. Mater. 94, 44–47 (2015).

A. M. Vlasova, V. P. Pilyugin, and O. V. Antonova, “Evolution of the microstructure of polycrystalline magnesium at mega plastic deformation in Bridgman anvils,” Russ. Phys. J. 59, 412–421 (2016).

B. I. Kamenetskii, Yu. N. Loginov, and A. Yu. Volkov, “Methods and devices for increasing the ductility of samples of brittle materials upon upsetting with a lateral support,” Zagotov. Proizv. Mashinostr., No. 9, 17–23 (2013).

A. Yu. Volkov, O. V. Antonova, B. I. Kamenetskii, I. V. Klyukin, D. A. Komkova, and B. D. Antonov, “Production, structure, texture, and mechanical properties of severely deformed magnesium,” Phys. Met. Metallogr. 117, 518–528 (2016).

O. V. Antonova, A. Yu. Volkov, D. A. Komkova, and B. D. Antonov, “Microstructure and texture of pure magnesium after room-temperature lateral extrusion,” Mater. Sci. Eng., A 706, 319–329 (2017).

O. V. Antonova, A. Yu. Volkov, B. I. Kamenetskii, and D. A. Komkova, “Microstructure and mechanical properties of thin magnesium plates and foils obtained by lateral extrusion and rolling at room temperature,” Mater. Sci. Eng., A 651, 8–17 (2016).

B. I. Kamenetskii, A. Yu. Volkov, A. L. Sokolov, O. V. Antonova, and I. V. Klyukin, RF Patent No. 2563077 (2014).

H. Qin, X. Zhang, and Q. Dong, “Microstructure and texture evolution for dynamic plastic deformed pure magnesium during isothermal annealing,” Mater. Sci. Eng., A 626, 94–101 (2015).

F. E. Hauser, P. R. Landon, and J. E. Dorn, “Fracture of magnesium alloys at low temperatures,” Trans. AIME 206, 589–594 (1956).

R. O. Kaibyshev and O. Sh. Sitdikov, “Low-temperature dynamic recrystallization of magnesium,” Metallofizika 15 (3), 68–76 (1993).

M. N. Yoo, “Slip, twinning, and fracture in hexagonal close-packed metals,” Metall. Trans. A 12, 409–418 (1981).

H. J. Choi, Y. Kim, J. H. Shin, and D. H. Bae, “Deformation behavior of magnesium in the grain size spectrum from nano- to micrometer,” Mater. Sci. Eng., A 527, 1565–1570 (2010).

S. E. Ion, F. J. Humphreys, and S. H. White, “Dynamic recrystallization and the development of microstructure during the high temperature deformation of magnesium,” Acta Metall. 30, 1909–1919 (1982).

ACKNOWLEDGMENTS

The work was performed within the framework of the state task according to the theme Davlenie, no. АААА-А18-118020190104-3 and was partly supported by the program of the Ural Branch, Russian Academy of Sciences (project no. 18-10-2-24) and by the Russian Foundation for Basic Research (project no. 18-33-00474).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by G. Salnikov

Rights and permissions

About this article

Cite this article

Komkova, D.A., Antonova, O.V. & Volkov, A.Y. On the Issue of the Improvement of Magnesium Plasticity by Cold Severe Plastic Deformation. Phys. Metals Metallogr. 119, 1120–1126 (2018). https://doi.org/10.1134/S0031918X18110108

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X18110108