Abstract

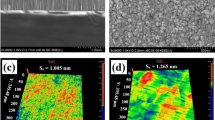

Nanocrystalline and conventional Co–Cr (ASTM F75) coatings were prepared by plasma spraying for possible orthopedic implant applications. Scanning electron microscopy and transmission electron microscopy were used to study the macrostructure and microstructure of the resultant sprayed coatings. The corrosion resistance was characterized by an in vitro potentiodynamic anodic polarization technique in a pseudophysiological solution. The nanocrystalline coating has higher porosity, lower corrosion current density, and less localized damage than that of the conventional one, demonstrating better application potential for orthopedic implants. A change in the atomic compositional difference between the grain interior and the grain boundary, the presence of residual strain in the grain interiors, and a change in the repassivation kinetics are discussed as possible explanations for the enhanced corrosion behavior observed. © 2001 Biomedical Engineering Society.

PAC01: 8165Kn, 8115Rs, 6146+w, 8780Rb, 6855-a, 5277Fv, 6837Hk, 8764Ee, 8107Bc, 6172Mm, 6837Lp

Similar content being viewed by others

References

Aust, K. T., U. Erb, and G. Palumbo. Interface control for resistance to intergranular cracking. Mater. Sci. Eng., A176:329, 1994.

Bard, A. J., and L. R. Faulkner. Electrical Methods: Fundamentals and Applications. New York: Wiley, 1980, pp. 26–34.

Birringer, R.Nanocrystalline materials. Mater. Sci. Eng., A117:33–43, 1989.

Chang, E., W. J. Chang, B. C. Wang, and C. Y. Yang. Plasma spraying of zirconia-reinforced hydroxyapatite composite coatings on titanium. I. Phase, microstructure, and bonding strength. J. Mater. Sci.: Mater. Med.8:193 and 201, 1997.

Deporter, D. A., P. A. Watson, R. M. Pilliar, M. Pharoah, D. C. Smith, M. Chipman, D. Locker, and A. Rydall. A prospective clinical study in humans of an endosseous dental implant partially covered with a powder-sintered porous coating: 3–to 4–year results. Int. J. Oral Maxillofac. Implants110:87, 1996.

Elkedim, O., H. S. Cao, C. Meunier, and E. Gaffet. Preparation of nanocrystalline copper by hot and cold compaction: Characterization of mechanical and electrochemical properties. Mater. Sci. Forum843:269–272, 1998.

Hantzsche, H. In: Proceedings of the 7th International Metal Spraying Conference, London, U.K., 10–14 September 1973, Paper No. 16, Abington, Cambridge, England: Welding Institute, 1974.

Heimann, R. B. Plasma-Spray Coating: Principles and Applications. New York: VCH, 1996, p. 19.

Huang, B., R. J. Perez, and E. J. Lavernia. Grain growth of nanocrystalline Fe-Al alloys produced by cryomilling in liquid argon and nitrogen. Mater. Sci. Eng., A255:124–132, 1998.

Hulbert, S. F., S. J. Morrison, and J. J. Klawitter. Tissue reaction to three ceramics of porous and nonporous structures. J. Biomed. Mater. Res.6:347, 1972.

Jiang, H. G., M. L. Lau, and E. J. Lavernia. Grain growth behavior of nanocrystalline Inconel 718 and Ni powder and coatings. Nanostruct. Mater.10:169, 1998.

Jiang, H., M. Rühle, and E. J. Lavernia. On the applicability of the x-ray diffraction line profile analysis in extracting grain size and microstrain in nanocrystalline materials. J. Mater. Res.14:549, 1999.

Khor, K. A., C. S. Yip, and P. Cheang. Post-spray hot isostatic pressing of plasma sprayed Ti-6Al-4V/hydroxyapatite composite coatings. J. Mater. Process. Technol.71:280, 1997.

Klawitter, J. J., and S. F. Hulbert, Application of porous ceramics for the attachment of load bearing internal orthopedic applications. J. Biomed. Mater. Res. Symp.5:61, 1971.

Lau, M. L., and E. J. Lavernia. Microstructural Evolution and Oxidation Behavior of Spraying. Mater. Sci. Eng., A272:222–229, 1999.

Lau, M. L., E. Strock, A. Fabel, C. J. Lavernia, and E. J. Lavernia. In: Multicomponent Ultrafine Microstructures, edited by L. E. McCandlish.

Luton, M. J., C. S. Jayanth, M. M. Disko, S. Matras, and J. Vallone. Synthesis and characterization of nanocrystalline Co-Cr coatings by plasma spraying. Mater. Res. Soc. Symp. Proc.132:79–86, 1989.

Maniatopoulos, C., R. M. Pilliar, and D. C. Smith. Threaded versus porous-surfaced designs for implant stabilization in bone-endodontic implant model. J. Biomed. Mater. Res.20:1309, 1986.

Mauer, R., U. Erb, and H. Gleiter. Intercrystalline corrosion: Factors controlling the enhanced corrosion near grain boundaries. Mater. Sci. Eng.63:L13, 1984.

Mishin, J., M. Vardelle, J. Lesinski, and P. Fauchais. Two-colour pyrometer for the statistical measurement of the surface temperature of particles under thermal plasma conditions. J. Phys. E20:620–625, 1987.

Pawlowski, L. The Science and Engineering of Thermal Spray Coatings. New York: Wiley, 1995, p. 86.

Rofagha, R., R. Langer, A. M. EI-Sherik, U. Erb, G. Palumbo, and K. T. Aust. The corrosion behavior of nanocrystalline nickel. Scr. Metall. Mater.25:2867, 1991.

Rofagha, R., U. Erb, D. Ostander, G. Palumbo, and K. T. Aust. The effects of grain size and phosphorous on the corrosion of nanocrystalline Ni-P alloys. Nanostruct. Mater.2:1, 1993.

Sobolev, V. V., J. M. Guilemany, and A. J. Martin. In: Proceedings of the 15th International Thermal Spray Conference, edited by C. Coddet. ASM International, Nice, France: ASM International, 1998, Vol. 1, p. 503.

Tellkamp, V. L., S. Dallek, D. Cheng, and E. J. Lavernia. Grain growth behavior of a nanostructured 5083 Al-Mg alloy. J. Mater. Res.16:938, 2001.

Thorpe, S. J., B. Ramaswami, and A. T. Aust. Corrosion and Auger studies of a nickel-base metal-metalloid glass. I. The effect of elemental interactions on passivity in the general corrosion of metglass 2826A. J. Electrochem. Soc.135:2162, 1988.

Vinogradov, A., T. Mimaki, S. Hashimoto, and R. Valiev. On corrosion of ultrafine grained copper produced by equi-channel angular pressing. Mater. Sci. Forum312–314:641–646, 1999.

Westhoff, R., G. Trapaga, and J. Szekely. Plasma-particle interactions in plasma spraying systems. Metall. Trans. B23:683, 1992.

Yamashita, M., T. Mimaki, S. Hashimoto, and S. Miura. Intergranular corrosion of copper and alpha-Cu-Al alloy bicrystals. Philos. Mag. A63:707, 1991.

Young, F., M. Spector, and C. H. Kresch. Porous titanium endosseous dental implants in Rhesus monkeys: Microradiography and histological evaluation. J. Biomed. Mater. Res.13:843, 1979.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Cheng, D., Tellkamp, V.L., Lavernia, C.J. et al. Corrosion Properties of Nanocrystalline Co–Cr Coatings. Annals of Biomedical Engineering 29, 803–809 (2001). https://doi.org/10.1114/1.1397790

Issue Date:

DOI: https://doi.org/10.1114/1.1397790