Abstract

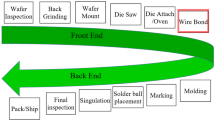

Gold (Au) wire is the preferred material for wire bonding in the semiconductor industry. However, the rising price of Au has become a key issue in IC assembly and design. To stay competitive, costs must be reduced. Copper (Cu) wire can also be used in wire bonding. Cu wire is cheaper than Au wire. To obtain the best yield of wire bonding and to reduce cost, this study develops an experimental approach by utilizing neural networks to establish the functional relationship between control factors and responses and then applying genetic algorithms to obtain the optimal control factor settings of the Cu wire bonding process. Using the developed approach for Cu wire bonding parameter design, the production yield increased from 98.5 to 99.65%, resulting in approximately USD 1.16 million in savings.

Similar content being viewed by others

References

Tam, S.C., Lim, L.E.N., and Quek, K.Y., “Application of Taguchi Methods in the Optimization of the Laser-Cutting Process,” Journal of Materials Processing Technology 29:63–74 (1992).

Li, C.H., Tsai, M.J., and Yang, C.D., “Study of Optimal Laser Parameters for Cutting QFN Packages by Taguchi’s Matrix Method,” Optics and Laser Technology 39:786–759 (2007).

Phadke, M.S., Quality Engineering Using Robust Design, Prentice-Hall, Englewood Cliffs, NJ (1989).

Taguchi, G., Chowdhury, S., and Wu, Y., Taguchi’s Quality Engineering Handbook, John Wiley & Sons, Hoboken, NJ (2004).

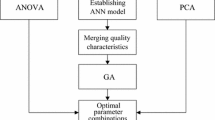

Cook, D.F., Ragsdale, C.T., and Major, R.L., “Combing a Neural Network with a Genetic Algorithm for Process Parameter Optimisation,” Engineering Application of Artificial Intelligence 13:391–396 (2000).

Solimanpur, M., and Ranjdoostfard, F., “Optimisation of Cutting Parameters Using a Multi-Objective Genetic Algorithm,” International Journal of Production Research 47(21):6019–6036 (2009).

Su, C.-T., and Yeh, C.-J., “Optimization of the Cu Wire Bonding Process for IC Assembly using Taguchi Methods,” Microelectronics Reliability 51(1):53–59 (2011)

Chang, P.-C., Wang, Y.-W., and Ting, C.-J., “A Fuzzy Neural Network for the Flow Time Estimation in a Semiconductor Manufacturing Factory,” International Journal of Production Research 46 (4):1017–1029 (2008).

Dayhoff, J.E., Neural Network Architectures, Van Nostrand Reinhold, New York (1990).

Fausett, L., Fundamentals of Neural Networks, Prentice-Hall International, Englewood Cliffs, NJ (1994).

Hornick, K., Stinchcombe, M., and White, H., “Universal Approximation of an Unknown Mapping and its Derivatives Using Multilayer Feedforward Networks,” Neural Networks 3(5):551–560 (1990).

Haupt, R.L., and Haupt, S.E., Practical Genetic Algorithms, 2nd Edition, John Wiley & Sons, Inc., Hoboken, NJ (2004).

Sivanandam, S.N., and Deepa, S.N., Introduction to Genetic Algorithms, Springer-Verlag, New York (2008).

Goldberg, D.E., Genetic Algorithms in Search, Optimisation, and Machine Learning, Addision-Wesley, New York (1989).

Hsu, C.-M., and Su, C.-T., “Multiobjective Machine-Component Ggrouping in Cellular Manufacturing: A genetic Algorithm,” Production Planning Control 9(2):155–166 (1998).

Hung, S.-Y., Chao, C.-K., Lin, T.-H., and Lin, C.-P., “Applying ANN/GA Algorithm to Optimize the High Fill-Factor Micrelens Array Fabrication Using UV Proximity Printing Process,” Journal of Micromechanics and Microengineering 15(12):2389–2397 (2005).

Khan, Z., Prasad, B., and Singh, T., “Machining Condition Optimization by Genetic Algorithms and Simulated Annealing,” Computers & Operations Research 24(7):647–657 (1997).

Man, K.F., and Tang, K.S., Genetic Algorithms: Concepts and Designs, Springer, New York (1999).

Karr, C.L., and Freeman, L.M., Industrial Applications of Genetic Algorithms, CRC Press, Boca Raton, FL (1999).

Castillo, E., Montgomery, D.C., and Maccarville, D.R., “Modified Desirability Functions for Multiple Response Optimisation,” Journal of Quality Technology 28(3):337–345 (1996).

Su, C.-T., and Chiang, T.-L., “Optimizing the IC Wire Bonding Process Using a Neural Networks/Genetic Algorithms Approach,” Journal of Intelligent Manufacturing 14(2):229–238 (2003).

Li, T.-S., Su, C.-T., and Chiang, T.-L., “Applying Robust Multi-Response Quality Engineering for Parameter Selection Using a Novel Neural-Genetic Algorithm,” Computers in Industry 50(1):113–122 (2003).

Hsu, C.-M., Su, C.-T., and Liao, D., “A Novel Approach for Optimizing the Optical Performance of the Broadband Tap Coupler,” International Journal of Systems Science 34(3):215–226 (2003).

Su, C.-T., Chen, M.-C., and Chan, H.-L., “Applying Neural Network and Scatter Search to Optimize Parameter Design with Dynamic Characteristics,” Journal of the Operational Research Society 56(10):1132–1140 (2005).

Chou, C.J., and Chen, L.F., “Combining Neural Networks and Genetic Algorithms for Optimizing the Parameter Design of Inter-Metal Dielectric Process,” International Journal of Production Research. DOI: 10.1080/00207543.2011.574499.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Su, C.T., Yeh, C.J., Chou, C.J. et al. An experimental approach to enhance Cu wire bonding yield through parameter optimization. Exp Tech 38, 29–36 (2014). https://doi.org/10.1111/j.1747-1567.2011.00799.x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1111/j.1747-1567.2011.00799.x