Summary and Conclusions

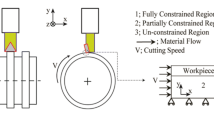

An experimental method of simulating the conditions of router action using a CNC lathe to test the cutting tool performance in peripheral trimming of composite material was developed. Validity of the proposed method is demonstrated by conducting the wear test on carbide inserts. Flank wear was not uniform, and the cutting edge shows abrasive tracks, grooves, and nose rounding. Chipping and edge rounding was dominant in interrupted cutting due to repeated impacts. Less grooving is seen in the interrupted case than in the continuous case. No signs of thermal damage or catastrophic failure was visible on any of the carbides used in this investigation. Machined surface damage was apparent under both cutting modes to the naked eye within 10 seconds of cutting time and life of the carbide is found to be less than 10 seconds.

Similar content being viewed by others

References

Strong, A.B., Fundamentals of Composites Manufacturing: Materials, Methods, and Applications, SME publication, 161–166 (1989).

Byrne, G. and Wunsch, U.E., “Composite Materials in Manufacturing Engineering Technical Developments and Applications,” NBST, Dublin, Ireland, (1986).

Konig. W., Wulf, Ch., Grab, P., and Willerscheid, H., “Machining of Fiber Reinforced Plastics,” Annals of CIRP, 34(2), 537–547 (1985).

Koplev, A., Lystrup, Aa., and Vorm, T., “The Cutting Process, Chips and Cutting Forces in Machining CFRP.,” Composites, 14(4), 372–373 (October 1983).

Spur, G. and Wunsch, U.E., “Turning of Fiber Reinforced Plastics,” Manufacturing Review, 1(2), 124–129 (June 1988).

Faridnia, M.R., “Preliminary Study on the Performance of Polycrystalline (PCD) Cutters in Machining of Graphite/Epoxy Composite,” MS Thesis, University of Washington, (August 1989).

Ramulu, M., Faridnia, M., Garbini, J.G., and Jorgensen, J.E., “Machining of Graphite/Epoxy Composite Materials with PCD Tools,” ASME J. of Engr Matls. and Tech., 113 430–436 (1991).

Ramulu, M., “Characterization of PCD Inserts for Use in Machining Graphite/Epoxy Materials,” Technical Report, Boeing Company, University of Washington, (December 1989).

Colligan, K. and Ramulu, M., “Delamination in Surface Plies of Graphite/Epoxy Caused by the Edge Trimming Process,” Processing and Manufacturing of Composite Materials, ASME Bound Volume, MD27, 113–125 (1991).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Ramulu, M., Rogers, E. Simulation of router action on a lathe to test the cutting tool performance in edge-trimming of graphite/epoxy composite. Exp Tech 18, 23–28 (1994). https://doi.org/10.1111/j.1747-1567.1994.tb02382.x

Published:

Issue Date:

DOI: https://doi.org/10.1111/j.1747-1567.1994.tb02382.x