Summary

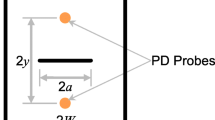

Conductive polymeric sensors can be used as crack-length gages. They have the advantages of being inexpensive, versatile in size and require inexpensive instrumentation. They also measure crack length continuously. The shape of these gages can be varied in several ways to improve their sensitivity. The gages with the ‘optimized’ or tapered shape overcome the principal disadvantages of rectangular gages, namely poor sensitivity at small crack lengths.

Similar content being viewed by others

References

BLH Electronics, “Crack Detection Coating,” Product Data Sheet 112-2 (1977).

Measurements Group, Inc., Catalog 500 Part A-Strain Gage Listings, 76–79 (1988).

Hartrun Corporation, “Fractomat for Fracture Mechanics, Fatigue Crack Growth” (1979).

Prabhakaran, R. and Lopez, O.F., “Application of Carbon Powder-polymer Composite as a Continuous Crack-length Sensor,” EXPERIMENTAL MECHANICS, 30 (4), 332–335 (1990).

Sahraoui, S., Lataillada, J. and Pouyet, J., “Crack-Propagation Velocity Measurements,” EXPERIMENTAL TECHNIQUES, 10 (6), 23–25 (1986).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Prabhakaran, R., Ramasamy, M. Shape optimization for a composite crack-length sensor. Exp Tech 16, 36–38 (1992). https://doi.org/10.1111/j.1747-1567.1992.tb00705.x

Published:

Issue Date:

DOI: https://doi.org/10.1111/j.1747-1567.1992.tb00705.x