Abstract

Background

The Swiss chemical industry produces large amounts of organic waste solvents. Some of these solvents cannot be recovered. A common option for the treatment of such organic waste solvents is the incineration in hazardous waste incinerators. Alternatively, the waste solvents can be used as fuel in cement production. On the one hand, solvent incineration in cement kilns saves fossil fuels such as coal and heavy fuel oil. On the other hand, fuel-bound emissions may change as well. These emission changes can either have a negative or a positive net ecological impact, depending on the chemical nature of the waste solvent used.

Goal and Scope

The aim of our work was to develop a multi-input allocation model, which allows one to calculate life cycle inventories for specific waste solvents. These LCIs can then be used in further applications, e.g. a comparison of different waste solvent treatment options.

Results and Discussion

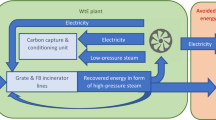

A multi-input allocation model was developed that takes into account the physico-chemical properties of waste solvents such as elementary composition and net calorific value. The model is based on a set of equations and data on fuel mix, fuel composition as well as transfer coefficients for heavy metals. The model calculates “avoided inputs” and “changes in emissions” which arise from substituting fossil fuels with waste solvents. Life cycle inventories can be calculated for specific waste solvents if the elementary composition and the net calorific value are known. The application of the model is illustrated in a case study on four waste solvents. The results show that solvent incineration in cement kilns generally reduces the overall impact of clinker production because fossil fuels are replaced. A sensitivity analysis revealed that the model is especially sensitive to the fuel mix and coal properties, such as net calorific value as well as the content of nitrogen and carbon. The transfer coefficients are also uncertain, but this uncertainty is not relevant as the amount of heavy metal emitted into the atmosphere is small.

Conclusions and Outlook

The proposed model serves to calculate inventory data for the combustion of liquid alternative fuels such as waste solvents in cement kilns. Although our model represents Swiss cement production conditions, it can be applied to other countries by fitting the most sensitive parameters of fuel mix and coal properties. In case the technology used is very different to the Swiss situation, the transfer coefficients also need to be adapted.

Similar content being viewed by others

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Seyler, C., Hellweg, S., Monteil, M. et al. Life Cycle Inventory for Use of Waste Solvent as Fuel Substitute in the Cement Industry - A Multi-Input Allocation Model (11 pp). Int J Life Cycle Assessment 10, 120–130 (2005). https://doi.org/10.1065/lca2004.08.173

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1065/lca2004.08.173