Abstract

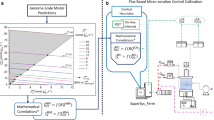

The purpose of the present work is to work out an approach for the development of software and the choice of hardware structures when designing subsystems for automatic control of technological processes realized in living objects containing limited space (microenvironment). The subsystems for automatic control of the microenvironment (SACME) under development use the Devices for Air Prophylactic Treatment, Aeroionization, and Purification (DAPTAP) as execution units for increasing the level of safety and quality of agricultural raw material and foodstuffs, for reducing the losses of agricultural produce during storage and cultivation, as well as for intensifying the processes of activation of agricultural produce and industrial microorganisms. A set of interconnected SACMEs works within the framework of a general microenvironmental system (MES). In this research, the population of baker’s yeast is chosen as a basic object of control under the industrial fed-batch cultivation in a bubbling bioreactor. This project is an example of a minimum cost automation approach. The microenvironment optimal control problem for baker’s yeast cultivation is reduced from a profit maximum to the maximization of overall yield by the reason that the material flow-oriented specific cost correlates closely with the reciprocal value of the overall yield. Implementation of the project partially solves a local sustainability problem and supports a balance of microeconomical, microecological and microsocial systems within a technological subsystem realized in a microenvironment maintaining an optimal value of economical criterion (e.g. minimum material, flow-oriented specific cost) and ensuring: (a) economical growth (profit increase, raw material saving); (b) high security, safety and quality of agricultural raw material during storage process and of food produce during a technological process; elimination of the contact of gaseous harmful substances with a subproduct during various technological stages; (c) improvement of labour conditions for industrial personnel from an ecological point of view (positive effect of air aeroionization and purification on human organism promoting strengthened health and an increase in life duration, pulverent and gaseous chemical and biological impurity removal). An alternative aspect of a controlled living microenvironment forming is considered.

Similar content being viewed by others

References

Alberts B, Bray D, Lewis J, Raff M, Roberts K, Watson JD (1989): Molecular biology of the cell. Garland Publishing, New York, London

Amelkin AA (1991): A mathematical model of baker’s yeast cultivation process. Izvestiya Vuzov. Food Technology (Russia) 4–6: 93–97

Amelkin AA, Amelkin AK (1997): Respiration modelling and control. In: Proceedings of the Third IFAC Symposium ‘Modelling and Control in Biomedical Systems (including Biological Systems)’ (University of Warwick, 23–26 March 1997), The Institute of Measurement and Control, London, the UK, Session 8: 1–6

Amelkin AA, Amelkin AK (1996): Mathematical modelling and control of aerobic organisms respiration. Biotekhnologiya (Russia) 9 (Sep.): 45–50

Amelkin AA, Blagoveschenskaya MM, Amelkin AK (2001a): The Microenvironmental Systems Project. In: Proceedings of the 6th IFAC Symposium on Cost Oriented Automation (Low Cost Automation 2001 -LCA 2001) (Berlin, October 8–9, 2001). Institut für berufliche Bildung, Zentrum Mensch-Maschine Systeme, Technische Universität Berlin, Berlin, Germany, 192–197

Amelkin AA, Blagoveschenskaya MM, Amelkin AK (2001b): The Subsystems of automatic control of living objects elaboration for food industry and agriculture illustrated with baker’s yeast cultivation, lysine biosynthesis and agricultural produce storage, processing, and presowing activation examples. Moscow State University of Applied Biotechnology, The 4th International Scientific and Technical Conference ‘Food. Ecology. Man.’Materials. Education Ministry of Russia, MGUAB, Moscow, Russia, 240–250

Amelkin AA, Blagoveschenskaya MM, Amelkin AK (2001c): The subsystems of automatic control of living objects elaboration for food industry and agriculture. Moscow State University of Food Production 70th Anniversary Collected Papers Edition. Education Ministry of Russia, MGUPP, Moscow, Russia, 440-452

Amelkin A, Blagoveschenskaya M, Amelkin AK, Amelkina A, Pletnyova A (2000a): Microenvironment control systems in agriculture, biotechnology, and food industry. In: Proceedings of the 2nd International Euro Environment Conference on Industry and Environmental Performance, CD-ROM (Álborg, 18–20 October 2000), Álborg Congress and Culture Centre, Álborg, Denmark

Amelkin A, Blagoveschenskaya M, Amelkin AK, Amelkina A, Pletnyova A (2000b): Microenvironmental systems: modelling, control, applications. In: Proceedings of the 14th Forum for Applied Biotechnology (Brugge, Belgium, 27–28 September 2000), Proceedings part I, GOM West-Vlaanderen, Med. Fac. Landbouww. Univ. Gent, 65/3a, Session 1 ‘Environmental Biotechnology’, Posters: 163–166

Amelkin AA, Kulikov AV, Pechkovsky AG (1995): The ways of automatic control of baker’s yeast fermentation. In: Proceedings of the IMACS/IFAC First International Symposium ‘Mathematical modelling and simulation in agriculture and bio-industries’ (M2SABI’95) (Brussels, 9–12 May 1995), Universite Libre de Bruxelles, Brussels, Belgium

Amelkin AK, Smirnov V, Mikhajlov V (1998): A device for air sanitary treatment. Patent of Russia No. 1623346, Patentee: Amelkin AA. Published in Bulletin of Inventions of Russia No. 15, Class F 24 F 3/16

Brook RC (1999): Potato storage experiments: Two decades of progress in technology and management. Michigan Potato Research Report 31: 154–162

But AI (1977): Application of electron-ion technique in food industry. Moscow, Food Industry: 88 pp.

Castrillo JI, Ugalde UO (1994): A general model of yeast energy metabolism in aerobic chemostat culture. Yeast 10: 185–197

Chizhevsky AL (1999): Air ions and life. Discussions with Tsiolkovsky. Moscow, Russia

Gaponov KP, Chugasova VA, Pozdnyakova VM (1984): Oxygen in fermentation processes. Moscow, ONTITEImicrobioprom, Russia

Lifshitz MN (1990): Aeroionification. Moscow, Russia

Lobanov YuV, Garmash JuV, Terletsky MJu (2000): Experience of application of FIX SCADA package of Intellution Company at ‘Ochakovo’ Moscow Brewing & Bottling Integrated Plant. Industrial Automated Control Systems and Controllers (Russia) 9

Muzychenko VA (1991) Electroaeroionization treatment of fruits and vegetables during storage. Abstract of thesis. Kiev, Ukraine

Okada W, Fukuda H, Morikawa H (1981): Kinetic expressions of ethanol production rate and ethanol consumption rate in baker’s yeast cultivation. J. Ferment. Technol. 59 (2): 103–109

Peringer P, Blachere H, Corrieu G, Lane AG (1974): A generalized mathematical model for the growth kinetics of Saccharomyces cerevisiae with experimental determination of parameters. Biotechnol. Bioeng. 16 (4): 431–454

Shkidchenko AN, Orlova VS, Termkhitarova NG, Rylkin SS (1983): The features of diauxic growth of Saccbaromyces cerevisiae. Microbiological Journal (Russia) 45 (6): 30–35

Skuchalina LN, Starosvetova EN, Sejtgaliev GM (2001): An importance of microenvironment for development of allergic diseases at child age. In: Proceedings of the 1st (5th) Congress of Paediatricians of Kazakhstan (Astana, 1–3 October 2001), Republician Society of Paediatricians of Kazakhstan, Scientific Center of Mother and Child Health Care, Kazakh State Medical University, Kazakhstan

Skulachev VP (1994): Chemiosmotic concept of the membrane bioenergetics: What is already clear and what is still waiting for elucidation? J. Bioen. Biomembr. 26: 589–598

Skulachev VP (1989): Biological membranes energetics. Moscow, Russia

Sonnleitner B, Käppeli O (1986): Growth of Saccharomyces cerevisiae is controlled by its limited respiratory capacity: formulation and verification of a hypothesis. Biotechnol. Bioeng. 28 (6): 927–937

Temnov AV, Stavrovskaya IG, Sirota TV, Kondrashova MN (2000): Self-organization of associations of mitochondria and the effect of negative air ions. Biophysics (Russia) 45 (1): 83–88

Volkenshtein MV (1988): Biophysics. Moscow, Russia

Wöhrer W, Röhr M (1981): Respiratory aspects of baker’s yeast metabolism in aerobic fed-batch cultures. Biotechnol. Bioeng. 23 (3): 567–581

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Amelkin, A.A., Blagoveschenskaya, M.M., Lobanov, Y.V. et al. Minimum specific cost control of technological processes realized in a living objects-containing microenvironment. Environ Sci & Pollut Res 10, 44–48 (2003). https://doi.org/10.1065/espr2002.10.132

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1065/espr2002.10.132