Abstract

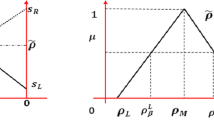

In this paper, an economic production quantity model for multi-item with storage space and budget constraints in a volume flexible manufacturing system is developed. Here it is assumed that the demand rate is constant up to a certain level of stock and after that it depends on stock itself. The unit production cost is taken to be a function of the finite production rate involving labour cost and wear and tear expenditure. Here, the inventory costs, selling price, storage space and available budget are defined imprecisely. Using necessary measure theory, the imprecise problem is reduced to deterministic problem. Here, necessity measure approach has been used for triangle fuzzy number and parabolic fuzzy number. Finally the crisp nonlinear optimization problem is solved by Fuzzy simulation, Contractive Mapping Genetic Algorithm and Generalized Reduced Gradient technique. The model is illustrated numerically and the results are compared.

Similar content being viewed by others

References

Bessaou M and Siarry P (2001). A genetic algorithm with real-value coding to optimize multimodal continuous function. Structural and Multi-disciplinary Optimization 23 (1): 63–74.

Chen JM and Liu CS (2008). Optimization of fuzzy production inventory model with unrepairable defective products. International Journal of Production Economics 113 (2): 887–894.

Cheng TCE (1991). An economic order quantity model with demand dependent unit production cost and imperfect production process. AIIE Transactions 23 (1): 23–28.

Dubois D and Prade H (1980). Fuzzy Sets and System—Theory and Application. Academic, Plenum Press: New York.

Dubois D and Prade H (1988). Possibility Theory. New York, London.

Gurnani C (1985). Economic analysis of inventory systems a reply. International Journal of Production Research 23 (4): 771–772.

Karim T, Reda B and Georges H (2011). Multi-objective supervisory flow control based on fuzzy interval arithmetic: Application for scheduling of manufacturing systems. Simulation Modelling Practice and Theory 19 (5): 1371–1383.

Khouja M (1995). The economic production lot size model under volume flexibility. Computer Operational Research 22 (5): 515–523.

Khouja M and Mehrez A (1994). Economic production lot size model with variable production rate and imperfect quality. Journal of Operational Research Society 45 (3): 1405–1417.

Last M and Eyal S (2005). A fuzzy-based lifetime extension of genetic algorithms. Fuzzy Sets and Systems 149 (1): 131–147.

Levin RI, Mcaughlim CP, Lamone RP and Kottas JF (1972). Production Management/Operations Management:(Contemporary Policy for Managing Operating System). McGraw-Hill: New York.

Liu B (2002). Toward fuzzy optimization without mathematical ambiguity. Fuzzy Optimization and Decision Making 1 (1): 43–63.

Liu B (2004). Uncertainty Theory: An Introduction to Its Axiomatic Foundations. Springer-Verlag: Heidelberg.

Liu B and Iwamura KB (1998). Chance constraint programming with fuzzy parameters. Fuzzy Sets and Systems 94 (2): 227–237.

Maiti MK (2011). A fuzzy genetic algorithm with varying population size to solve an inventory model with credit-linked promotional demand in an imprecise planning horizon. European Journal of Operational Research 213 (3): 96–106.

Maiti MK and Maiti M (2006). Fuzzy inventory model with two warehouses under possibility constraints. Fuzzy Sets and Systems 157 (1): 52–73.

Maity K (2011). Possibility and necessity representations of fuzzy inequality and its application to two warehouse production-inventory problem. Applied Mathematical Modelling 35 (3): 1252–1263.

Maity K and Maiti M (2008). A numerical approach to a multi-objective optimal inventory control problem for deteriorating multi-items under fuzzy inflation and discounting. Computers & Mathematics with Applications 55 (8): 1794–1807.

Michalewicz Z (1992). Genetic Algorithms+Data Structure=Evolution programs. Springer Verlag: Berlin.

Moon I, Gallego G and Simchilevi D (1991). Controllable production rates in a family production context. International Journal of Production Research 29 (12): 2459–2470.

Nazzal D, Mollaghasemi M, Hedlund H and Bozorgi A (2012). Using genetic algorithms and an indifference-zone ranking and selection procedure under common random numbers for simulation optimisation. Journal of Simulation 6 (1): 56–66.

Pezzellaa F, Morgantia G and Ciaschettib G (2008). A genetic algorithmfor the flexible job-shop scheduling problem. Computers & Operations Research 35 (10): 3202–3212.

Taleizadeha AA, Niakib STA and Nikousokhanc R (2011). Constraint multi-product joint-replenishment inventory control problem using uncertain programming. Applied Soft Computing 11 (8): 5143–5154.

Wu KS, Ouyang LY and Yang CT (2006). An optimal replenishment policy for non-instantaneous deteriorating items with stock dependent demand and partial backlogging. International Journal of Production Economics 101 (2): 369–384.

Zadeh LA (1978). Fuzzy sets as a basis for a theory of possibility. Fuzzy Sets and Systems 1 (1): 3–28.

Zhou YW and Yang SL (2005). A two-warehouse inventory model for items with stock-level-dependent demand rate. International Journal of Production Economics 95 (2): 215–228.

Zimmerman HJ (1987). Fuzzy Sets, Decision-making and Expert System. Kluwwer Academic Publishers: Boston.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jana, D., Maity, K., Das, B. et al. A fuzzy simulation via contractive mapping genetic algorithm approach to an imprecise production inventory model under volume flexibility. J Simulation 7, 90–100 (2013). https://doi.org/10.1057/jos.2012.23

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1057/jos.2012.23