Abstract

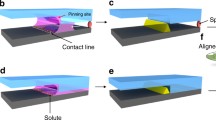

THE formation of patterned structures on micrometre-length scales is essential for the fabrication of many electronic, optical and mechanical devices1. Patterning technologies are well established for semiconductors and metals, but are relatively undeveloped for organic polymers (with the notable exception of the specialized polymers used in photolithography1). Polymeric replicas of some structures have been formed by filling them with monomers which are subsequently polymerized2á¤-5. But these procedures have important limitations, in that the usually involve the destruction of the template structure, or the resulting structures are not sufficiently regular for most applications. Here we describe a general moulding procedure which does not suffer from these limitations. For the mould we use the continuous network of channels formed when a substrate and a patterned elastomeric master are placed in intimate contact. A low-viscosity polymer precursor is placed in contact with the network, which then fills spontaneously by capillary action. After cross-linking the precursor, the master is removed (and can be reused), leaving a patterned polymer layer; depending on the choice of substrate, patterned free-standing films can be similarly produced.

Similar content being viewed by others

References

Moreau, W. M. Semiconductor Lithography: Principles and Materials (Plenum, New York, 1988).

Haverkorn van Rijsewijk, H. C., Legierse, P. E. J. & Thomas, G. E. Philips tech. Rev. 40, 287–297 (1982).

Palmer, C. Spectroscopy 102, 14–15 (1995).

Martin, C. M. Accts Chem. Res. 28, 61–68 (1995).

Kumar, A. & Whitesides, G. M. Appl. Phys. Lett. 63, 2002–2004 (1993).

Kumar, A., Biebuyck, H. A. & Whitesides, G. M. Langmuir 10, 1498–1511 (1994).

Wilbur, J. L., Kumar, A., Kim, E. & Whitesides, G. M. Adv. Mater. 7–8, 600–604 (1994).

Abbott, N. L., Folkers, J. P. & Whitesides, G. M. Science 257, 1380–1382 (1992).

Tech. Rep. Q3-6696 (Dow Corning, Midland, MI, 1991).

Tech. Rep. 10-177-87 (Dow Corning, Midland, Ml, 1987).

Whitesides, G. M. & Laibinis, P. E. Langmuir 6, 87–96 (1990).

Whitesides, G. M., Biebuyck, H. A., Folkers, J. P. & Prime, K. L. J. Adhes. Sci. Tech. 5, 57–69 (1991).

Rowlinson, J. S. & Widom, B. Molecular Theory of Capillarity 7–12 (Oxford Univ. Press, New York, 1982).

Hudson, J. B. Surface Science 49–69 (Butterworth-Heinemann, Boston, 1990).

Myers, D. Surfaces, Interfaces, and Colloids 87–109 (VCH, New York, 1991).

Dong, M. & Chatzis, I. J. Colloid Interf. Sci. 172, 278–288 (1995).

Ferguson, G. S., Chaudhury, M. K., Sigal, G. B. & Whitesides, G. M. Science 253, 776–778 (1991).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kim, E., Xia, Y. & Whitesides, G. Polymer microstructures formed by moulding in capillaries. Nature 376, 581–584 (1995). https://doi.org/10.1038/376581a0

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1038/376581a0

- Springer Nature Limited

This article is cited by

-

Fabrication of Hollow Polymer Microchannels Using the MIMIC Technique with Subsequent Heat Treatment

International Journal of Precision Engineering and Manufacturing (2021)

-

Hydrogels for Efficient Multiplex PCR

Biotechnology and Bioprocess Engineering (2020)

-

High-throughput microstructure printing technology using inflatable thin membrane with microchannel

The International Journal of Advanced Manufacturing Technology (2019)

-

Engineering polymer MEMS using combined microfluidic pervaporation and micro-molding

Microsystems & Nanoengineering (2018)

-

Soft lithography based on photolithography and two-photon polymerization

Microfluidics and Nanofluidics (2018)