Abstract

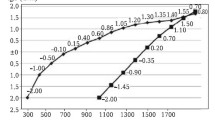

A heating module for service in oxidizing gas media at temperatures up to 1700°C is proposed. Results of an analysis of the thermally stressed state of lanthanum chromite-based heaters designed in various configurations for use in the heating module are reported.

Similar content being viewed by others

REFERENCES

”New high-temperature tube furnaces to 1800°C,” Interceram., 44(5), 364–365 (1995).

M. B. Gutman (ed.), Materials for Electric Thermal Power Units. Handbook [in Russian], Énergoatomizdat, Moscow (1987).

V. I. Bezruchenko, “A high-temperature laboratory electric furnace LVP-1700/70,” Steklo Keram., No. 5/6, 9–11 (1994).

S. A. Suvorov and A. P. Shevchik, “RF Patent No. 2123241, A method for fabrication of a heating tube element with controlled electric conductivity,” Izobreteniya, No. 34 (1998).

M. A. Andrianov, V. P. Balkevich, and V. E. Sotnikov, “Lanthanum chromite used for fabricating heaters,” Ogneupory, No. 11, 42–46 (1980).

S. A. Suvorov, V. P. Migal', and E. V. Gusarova, “An analysis of transient thermal fields and thermal stresses in tubular resistance heaters,” Ogneupory, No. 3, 48–51 (1989).

B. M. Barykin, V. G. Gordon, and É. G. Spiridonov, “Nonfired conducting chromite-based materials for magnetohydrodynamic (MHD) generators,” in: High-Temperature Materials for MHD Electrical Systems [in Russian], Nauka, Moscow (1983), pp. 34–38.

N. Sakai, K. Yamaji, T. Horita, H. Yokokawa, T. Kawada, and M. Dokija, “Oxygen transport properties of La1-xCaxCrO3-? as an interconnect material of solid oxide fuel cell,” J. Electrochem. Soc., 147(9), 3178–3182 (2000).

S. A. Suvorov and A. P. Shevchik, “RF Patent No. 2104984, Multicomponent resistive material and the precursor mixture,” Izobreteniya, No. 5 (1998).

B. Hawkes, The CADCAM Process, Pitman Publ., London (1988).

D. Yu. Ostrovoi, G. A. Gogotsi, S. A. Suvorov, and A. P. Shev-chik,“Strain and fracture of a ceramic based on lanthanum chromite,” Ogneup. Tekh. Keram., No. 7/8, 10-20 (2002).

I. A. Birger, B. F. Shorr, and G. B. Iosilevich, Strength Analysis of Machine Components [in Russian], Mashinostroenie, Moscow (1993).

S. A. Suvorov and A. P. Shevchik, “Chemical equilibria involving lanthanum chromite,” Novye Ogneupory, No. 12, 27–32 (2003).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Suvorov, S.A., Shevchik, A.P. A Heating Module Equipped with Lanthanum Chromite-Based Heaters. Refractories and Industrial Ceramics 45, 196–200 (2004). https://doi.org/10.1023/B:REFR.0000036729.24986.e3

Issue Date:

DOI: https://doi.org/10.1023/B:REFR.0000036729.24986.e3