Abstract

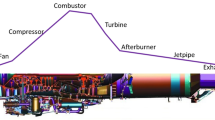

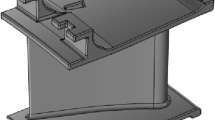

The development of rotor seals for gas-turbine engines is reported using Si3N4 – BN-based composite materials molded by hot-pressing technology. The mechanical and thermophysical properties of the newly-developed materials are determined and compared with results of a thermal stress analysis by numerical simulation method. Potential use of rotor seals of different design, in particular, multilayer components, for practical applications is discussed.

Similar content being viewed by others

REFERENCES

A Review of Foreign Patents on Applications of Ceramics in the Components of Gas-Turbine Engines, No. 207 [in Russian], TsIAM, Moscow, 62–78 (1985).

K. Tanaka, M. Yoshida, T. Kubo, et al., “Development and evaluation of ceramic components for small gas turbine engine,” in: ASME TURBOEXPO'2000, May 8–11, 2000, Münich, Germany.

N. I. Ershova, I. Yu. Kelina, and V. M. Zemlyanskaya, “Hotpressed composite materials in the silicon nitride-boron nitride system,” Ogneupory, No. 11, 17–21 (1995).

N. I. Ershova and I. Yu. Kelina, “Multilayer ceramic components from silicon nitride-boron nitride composite material,” Ogneup. Tekh. Keram., No. 5, 6–10 (1997).

V. V. Vikulin and I. N. Kurskaya, “Structural materials based on the reaction-bound silicon nitride,” Ogneupory, No. 9 (1990).

R&D Report “Mechanical, Thermophysical, and Operational Characteristics of Structural Ceramics in Engine Building,” File No. 01.87.0078328, Part II. Thermophysical and Operational Characteristics [in Russian], Institute for Engineering Physics Problems in Power Engineering, Lithuanian Academy of Sciences (IFTPE), Kaunas (1989).

H. L. Ekkehard and M. V. Swain, “Fracture toughness and thermal shock behavior of silicon nitride-boron nitride ceramics,” J. Am. Ceram. Soc., 75(1), 67–70 (1992).

I. Keiishiro, F. Toshiaki, and U. Ryoji, “Development of machinable Si3N4-BN composite ceramics,” Kawasaki Seitetsu Siho T (Kawasaki Steel Giho), 21(4), 281–286 (1989).

Technical Characteristics of Ceramic Materials Available from FCT Technologie GmbH. Prospectus (2001).

V. Dauknis, K. Kazakyavichyus, G. Prantskyavichyus, and V. Yurenas, Thermal Stability of Refractory Ceramics [in Russian], Mintis, Vilnius (1971).

I. Keiishiro, F. Toshiaki, O. Kazuki, et al., “Microstructure and mechanical properties of Si3N4-BN composite ceramics prepared by slip casting,” Tetsu To Hagane, J. Iron Steel Inst. Jpn., 5(9), 1612–1619 (1989).

I. Yu. Kelina, N. I. Ershova, and E. N. Chasovskoi, “The behavior of composite materials based on silicon and boron nitride subjected to thermal shock,” Ogneup. Tekh. Keram., No. 12, 12–17 (1998).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kelina, I.Y., Ershova, N.I., Arakcheev, A.V. et al. Rotor Seals for Gas-Turbine Engines Fabricated from Si3N4 – BN High-Temperature Composite Materials. Refractories and Industrial Ceramics 45, 185–189 (2004). https://doi.org/10.1023/B:REFR.0000036727.64065.7e

Issue Date:

DOI: https://doi.org/10.1023/B:REFR.0000036727.64065.7e