Abstract

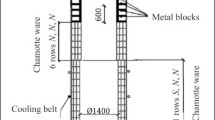

The KSVKh-1 refractory mixture (available from the REIN JSC) was tested as a material for the lining of an LFR 30/CSH channel-type induction mixer under industrial conditions at the AMO ZIL automobile plant. The mixture was used to prepare the lining for the bath and nozzles by a castable technology; it showed a high resistance to wear and good service characteristics for a period of one year at least.

Similar content being viewed by others

REFERENCES

E. E. Grishenkov, L. Ya. Kopeikina, V. P. Enenko, et al., "Refractories for metal melting furnaces," Novye Ogneupory, No. 1, 49-59 (2002).

V. I. Sizov, V. N. Tonkov, L. Ya. Kopeikina, et al., "Corundum-based mixtures for the lining of iron-melting furnaces," Novye Ogneupory, No. 9, 51-53 (2001).

V. I. Sizov, V. N. Tonkov, K. A. Karpets, and I. A. Pikhutin, "Mixtures for the refractory lining in the production and processing of aluminum and Al-based alloys," Novye Ogneupory, No. 1, 36-40 (2002).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Enenko, V.P., Chernov, I.A., Sizov, V.I. et al. The Use of a Corundum Mixture for the Lining of Channel-Type Iron-Soaking Induction Furnaces. Refractories and Industrial Ceramics 44, 289–291 (2003). https://doi.org/10.1023/B:REFR.0000009031.71845.5e

Issue Date:

DOI: https://doi.org/10.1023/B:REFR.0000009031.71845.5e