Abstract

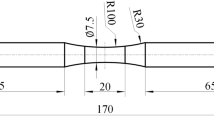

The finite-element method is used to study the effect of sand shell size on compaction and shape change during compaction of billets formed from the hot products of self-propagating high-temperature synthesis. The extreme nature of the change in billet density in relation to shell thickness that governs its reserve of compressibility is established. In order to make high-density billets it is necessary that shell compressibility reserve is higher than that of the synthesis products. With decrease in shell radial dimensions there is distortion of billet shape due to a nonuniform stress-strained state close to the side surface of the tool with external friction.

Similar content being viewed by others

REFERENCES

M. S. Kovalchenko, Theoretical Bases of Hot Forming of Porous Materials [in Russian], Nauk. Dumka, Kiev (1980).

A. P. Amosov and A. F. Fedotov, “Finite-element plane model of the thermal regime in self-propagating hightemperature synthesis of billets in a friable shell,” Inzh.-Fiz. Zhurn., 24, No. 5, 160-166 (2001).

A. P. Amosov and A. F. Fedotov, “Modelling by the energy method of hot compaction of SHS products for the system titanium–carbon–nickel. II. Results of modelling and experimental studies,” Poroshk. Metall., Nos. 1–2, 8-14 (2002).

A. P. Amosov and A. F. Fedotov, “Modelling by the energy method of hot compaction of SHS products for the system titanium–carbon–nickel. I. Structural state, rheological models, and energy relationships,” Poroshk. Metall., Nos. 11–12, 28-34 (2001).

A. F. Fedotov, “Plasticity and internal friction characteristics of friable materials of thermal insulating shells for compacting SHS products,” Ogneupory i Tekhn. Keramika, No. 7, 14-17 (1997).

B. A. Druyanov, Applied Ductility Theory for Porous Bodies [in Russian], Mashinostroenie, Moscow (1989).

A. F. Fedotov, “Rheological properties of a porous viscous body with a liquid phase,” Izv. Vyssh. Uchebn. Zaved., Mashinostroenie, Nos. 10–12, 8-14 (1997).

V. P. Radchenko, A. F. Fedotov, and M. A. Ermolenko, “Numerical solution of the boundary problem of plastic deformation with SHS-compaction in a shell of uniform friable material,” Izv. Vyssh. Uchebn. Zaved.,, Mashinostroenie, No. 1, 15-24 (2002).

S. S. Kiparisov and G. A. Libenson, Powder Metallurgy [in Russian], Metallurgiya, Moscow (1991).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Amosov, A.P., Radchenko, V.P. & Fedotov, A.F. Effect of Shell Dimensions on Compaction and Shape Change during SHS-Pressing. Powder Metallurgy and Metal Ceramics 43, 229–235 (2004). https://doi.org/10.1023/B:PMMC.0000042455.62526.69

Issue Date:

DOI: https://doi.org/10.1023/B:PMMC.0000042455.62526.69