Abstract

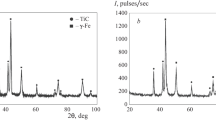

Milling of wear-resistant steel and titanium carbide powders is studied with an attrition mill rotation rate of 980 rpm. The physical and technological properties of powders and particle size are determined. Particle shape and the change in material chemical composition during milling are studied. It is established that steel powder cannot be milled to particle sizes less than 3.6 μm whereas a mixture of steel and titanium carbide can be milled to a fine state (0.3 μm). Powders with a size of about 1 μm neither flow nor are formable. Use of benzene as a milling medium makes it possible to prevent steel powder oxidation, but the carbon content in titanium carbide decreases. During milling of the main part of the charge to a fine state rather large steel particles (up to 50 μm) remain.

Similar content being viewed by others

REFERENCES

Yu. G. Gurevich, V. K. Narva, and N. R. Frage, Carbide Steels [in Russian], Metallurgiya, Moscow (1988).

Y. Kyubarsepp, Hard Alloys with a Steel Binder [in Russian], Valgus TTU, Tallinn (1991).

I. D. Bykov, G. P. Dubov, Yu. F. Bokii, et al., “Experience of preparing tools from carbide steels,” Poroshk. Metall., No. 5, 40-44 (1984).

L. A. Poznyak, Tool Steels [in Russian], Nauk. Dumka, Kiev (1996).

V. N. Eremenko, Titanium Carbide and Heat-Resistant Materials Based on It [in Russian], Izd. Akad. Nauk UkrSSR, Kiev (1954).

A. V. Antsiferov, V. T. Zubkova, S. A. Kameneva, et al., “Use of a vertical vibration mill for grinding and mixing carbide steel components,” Poroshk. Metall., Nos. 5–6, 4-8 (1998).

V. E. Matsera, V. S. Pugin, and A. G. Dobrovol'skii, “Grinding of powders in a planetary mill,” Poroshk. Metall., No. 6, 11-15 (1973).

R. A. Andrievskii, A. Zh. Dzneladze, L. N. Petrov, and S. V. Yudin, “Grinding of titanium carbide and nitride prepared by SHS in an attrition mill,” Poroshk. Metall., No. 11, 1-3 (1983).

V. M. Shelekhina, A. N. Shevno, A. A. Kolesnikov, and V. A. Pryanichnikov, “Some features of grinding powders in an attrition mill,” Poroshk. Metall., Vyssheish. Shkola, Minsk, No. 5, 12-14 (1981).

I. M. Fedorchenko and R. A. Andrievskii, Bases of Powder Metallurgy [in Russian], Izd. Akad. Nauk UkrSSR, Kiev (1963).

GOST 23402-78, “Metal powders. Particle size determination,” Intro. 01.01.80.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Pavlygo, T.M., Plomod'yalo, L.G., Plomod'yalo, R.L. et al. Milling of Carbide-Steel Powder Components and Their Mixtures in an Attrition Mill. Powder Metallurgy and Metal Ceramics 43, 223–228 (2004). https://doi.org/10.1023/B:PMMC.0000042454.39244.8e

Issue Date:

DOI: https://doi.org/10.1023/B:PMMC.0000042454.39244.8e