Abstract

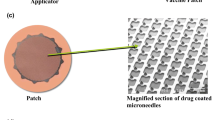

Purpose: Fluid-bed spray-coating process is widely used to prepare non-protein pharmaceutical solid dosage forms using macro-size seed particles (200-1000 μm) at kilogram batch sizes. In this study we developed a small-scale fluid-bed spray-coating process (20 g) to produce micro-sized vaccine powder formulations (40-60 μm) for epidermal powder immunization (EPI)

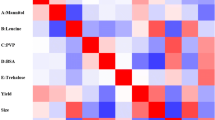

Methods: A bench-top spray coater was used to spray two vaccines, diphtheria toxoid (dT) and alum-adsorbed hepatitis-B surface antigen (Alum-HBsAg), onto crystalline lactose particles of 40-60 μm in diameter. Particle properties such as particle size, surface morphology, and degree of particle agglomeration were determined. Protein stability was analyzed by sodium dodecyl sulfate-polyacrylamide gel electrophoresis. The immunogenicity of the vaccine was evaluated in vivo by needle injection and epidermal powder immunization (EPI) of mice or guinea pigs.

Results: Coating feasibility was demonstrated for both vaccine formulations containing different excipients. However, the nature of the vaccine antigen appeared to affect coating feasibility in terms of particle agglomeration considerably. Delivery of spray-coated dT and alum-HBsAg through EPI to mice and guinea pigs, respectively, generated significant antibody responses, at a level comparable to liquid formulation delivered subcutaneously through needle/syringe injection.

Conclusions: The new spray-coating process represents an important technical advance and may provide a useful tool for developing high-valued biopharmaceutical powder formulations for novel applications. The strong in vivo performance of the coated dT and alum-HBsAg powders by EPI further demonstrated that spray-coating is a viable dry powder formulation process and the skin's epidermal layer presents an efficient vaccine delivery route.

Similar content being viewed by others

References

Y.-F. Maa, and S. J. Prestrelski. Biopharmaceutical powders: Particle formation and formulation considerations (review). Curr. Pharm. Biotechnol. 1:283-302 (2000).

W. R. Gombotz, and L. R. Brown. Process for producing small particles of biologically active molecules. International Patent Application PCT/US90/02421 (1990).

Y.-F. Maa, P.-A. Nguyen, T. D. Sweeney, S. J. Shire, and C. C. Hsu. Protein inhalation powder: Spray drying vs. spray freeze drying. Pharm. Res. 16:249-254 (1999).

H. R. Constantino, L. Firouzabadian, K. Hogeland, C. Wu, C. Beganski, K. G. Carrasquilla, M. Cardova, K. Griebenow, S. E. Zale, and M. A. Tracy. Protein spray freeze drying. Effect of atomisation conditions on particle size and stability. Pharm. Res. 17:1374-1383 (2000).

M. A. Winters, B. L. Knutson, P. G. Debenedetti, H. G. Sparks, T. M. Przybycien, C. L. Stevenson, and S. J. Prestrelski. Precipitation of proteins in supercritical carbon dioxide. J. Pharm. Sci. 85:586-594 (1996).

S.-D. Yeo, G.-B. Lim, P. G. Debenedetti, and H. Bernstein. Formation of microparticulate protein powders using a supercritical fluid antisolvent. Biotechnol. Bioeng. 41:341-346 (1993).

P. York, B. Y. Shekunov, and G. O. Humphreys. Microfine particle formation by SEDS (solution enhanced dispersion by supercritical fluids): Scale up by design. Respiratory Drug Delivery VI Proceedings. Interpharm Press, USA 1998 pp. 169-175.

K. Masters. Spray-Drying Handbook, 4th ed, J. Wiley & Sons, New York, 1985.

J. Broadhead, S. K. Edmond Rouan, and C. T. Rhodes. The spray-drying of pharmaceuticals. Drug Dev. Ind. Pharm. 18:1169-1206 (1992).

J. Broadhead, S. K. Edmond Rouan, I. Hau, and C. T. Rhodes. The effect of process and formulation variables on the properties of spray-dried —galactosidase. Pharm. Pharmacol 64:458-467 (1994).

M. Mumenthaler, C. C. Hsu, and R. Pearlman. Feasibility study on spray-drying protein pharmaceuticals: Recombinant human growth hormone and tissue-type plasminogen activator. Pharm. Res. 11:12-20 (1994).

Y.-F. Maa, P.-A. Nguyen, and C. C. Hsu. Spray drying of air-sensitive recombinant human growth hormone. J. Pharm. Sci. 87:152-159 (1998).

Y.-F. Maa, P.-A. Nguyen, J. D. Andya, N. Dasovich, T. D. Sweeney, S. J. Shire, and C. C. Hsu. Effect of spray drying and subsequent processing conditions on residual moisture content and physical/biochemical stability of protein inhalation powders. Pharm. Res. 15:768-775 (1998).

Y.-F. Maa, R. H. Costantino, P.-A. Nguyen, and C. C. Hsu. The effect of operating and formulation variables on the morphology of spray-dried protein particles. Pharm. Dev. Technol. 2:213-223 (1997).

K. W. Olsen. Batch fluid-bed processing equipment: a design overview; Part I. Pharm. Technol 13:34-46 (1989).

K. W. Olsen. Batch fluid-bed processing equipment: a design overview; Part II. Pharm. Technol 13:46-50 (1989).

Y. Fukumori, H. Ichikawa, Y. Yamaoka, E. Akaho, Y. Takeuchi, T. Fukuda, R. Kanamori, and Y. Osako. Effect of additives on physical properties of fine ethyl cellulose microcapsules prepared by the Würster process. Chem. Pharm. Bull 39:164-169 (1991).

Y. Fukumori, H. Ichikawa, Y. Yamaoka, E. Akaho, Y. Takeuchi, T. Fukuda, R. Kanamori, and Y. Osako. Microgranulation and encapsulation of pulverized pharmaceutical powders with ethyl cellulose by the Würster process. Chem. Pharm. Bull 39:1806-1812 (1991).

Y. Fukumori, H. Ichikawa, K. Jono, T. Fukuda, and Y. Osaka. Effect of additives on agglomeration in aqueous coating with hydroxypropyl cellulose. Chem. Pharm. Bull 41:725-730 (1993).

Y.-F. Maa, P.-A. Nguyen, and C. C. Hsu. Spray coating of rhDNase on lactose: Effect of system design, operational parameters, and protein formulations. Int. J. Pharm. 144:47-59 (1996).

Y.-F. Maa and C. C. Hsu. Feasibility of protein spray-coating using a fluid-bed würster processor. Biotech. Bioeng. 53:560-566 (1997).

D. Chen, R. L. Endres, C. A. Erickson, K. F. Weis, M. W. McGregor, Y. Kawaoka, and L. G. Payne. Epidermal immunization by a needle-free powder delivery technology: Immunogenicity of influenza vaccine and protection in mice. Nat. Med. 6:1187-1190 (2000).

D. Chen, C. A. Erickson, R. L. Endres, S. B. Periwal, Q. Chu, C. Shu, Y.-F. Maa, and L. G. Payne. Adjuvantation of epidermal powder immunization. Vaccine 19:2908-2917 (2001).

S. B. Flohe, C. Bauer, and H. Moll. Antigen-pulsed epidermal Langerhans cells protect susceptible mice from infection with the intracellular parasite Leishmania major. Euro. J. Immunol. 28:3800-3811 (1998).

C. Condon, S. C. Watkins, C. M. Celluzzi, K. Thompson, and L. D. Falo Jr. DNA-based immunization by in vivo transfection of dendritic cells. Nat. Med. 2:1122-1128 (1996).

A. M. Polillio and J. Kiley. Does a needleless injection system reduce anxiety in children receiving intramuscular injections? Pediatr. Nurs. 23:46-49 (1997).

W. S. Shalaby. Development of oral vaccines to stimulate mucosal and systemic immunity: barriers and novel strategies. Clin. Immunol. Immunopathol. 74:127-134 (1995).

L. C. Freytag and J. D. Clements. Bacterial toxins as mucosal adjuvants. Curr. Top. Microbiol. Immunol. 236:215-236 (1999).

M. I. Zapata, J. R. Feldkamp, G. E. Peck, J. L. White, and S. L. Hem. Mechanism of freeze-thaw instability of aluminum hydroxycarbonate and magnesium hydroxide gels. J. Pharm. Sci. 73:3-8 (1984).

D. Diminsky, N. Moav, M. Gorecki, and Y. Barenholz. Physical, chemical, and immunological stability of CHO-derived hepatitis B surface antigen (HBsAg) particles. Vaccine 18:3-17 (1999).

H. S. Warren, F. R. Vogel, and L. A. Chedid. Current status of immunological adjuvants. Annu. Rev. Immunol. 4:369-388 (1986).

C. R. Alving, B. Detrick, R. L. Richards, M. G. Lewis, A. Shafferman, and G. A. Eddy. Novel adjuvant strategies for experimental malaria and AIDS vaccines. Ann. N.Y. Acad. Sci. 690:265-275 (1993).

Y.-F. Maa, L. Zhao, L. G. Payne, and D. Chen. Stabilization of alum-adjuvanted vaccine powder formulation: Mechanism and application. J. Pharm. Sci. 92:319-332 (2003).

S. D. Allison, M. C. Manning, T. W. Randolph, K. Middleton, A. Davis, and J. F. Carpenter. Optimization of storage conditions of lyophilized actin using combination of disaccharides and dextran. J. Pharm. Sci. 89:199-214 (2000).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Maa, YF., Ameri, M., Rigney, R. et al. Spray-Coating for Biopharmaceutical Powder Formulations: Beyond the Conventional Scale and Its Application. Pharm Res 21, 515–523 (2004). https://doi.org/10.1023/B:PHAM.0000019307.27058.a1

Issue Date:

DOI: https://doi.org/10.1023/B:PHAM.0000019307.27058.a1