Abstract

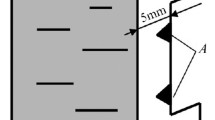

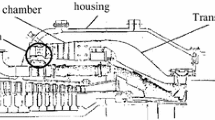

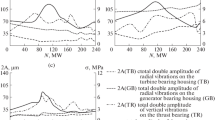

We study defects formed on the outer and inner surfaces of the input collector of water economizer of a TPP-312 boiler at the Ladyshyn thermal power plant. The collector was operating at a working temperature of 280°C under a pressure of 29.4 MPa. The period of operation of the collector prior to the analyzed maintenance shutdown was equal to 182,817 h (with 522 startups and shutdowns). A net of radial thermal fatigue cracks emerging from the holes made to attach coiled pipes (by welding) was found on the inner and outer surfaces of the collector. We propose a method for the evaluation of the degree of damage to the collector based on the computer processing of the images of cracks. To distinguish cracks in the images, we applied the method of segmentation of digital images based on the visual perception of local contrast. To determine the orientation of cracks, we used a model of crack in the form of a connected set of linear segments. As a result, the required orientation of cracks was determined by comparing the cracks with special radially oriented patterns. As a measure of damage, we used the distribution of the normed area occupied by the cracks inside the concentric circles drawn around the hole in the collector.

Similar content being viewed by others

REFERENCES

O. Z. Student, B. P. Rusyn, B. V. Kysil', et al., "Quantitative analysis of structural changes in steel caused by high-temperature holding in hydrogen," Fiz.-Khim. Mekh. Mater., 39, No. 1, 22–28 (2003).

T. Stahiv, O. Student, I. Dzioba, and M. Gajewski, "Fatigue crack growth in 0.15C-2Cr-Mo-V steel after its high-temperature hydrogen degradation," in: A. Neimitz, I. V. Rokach, D. Kocanda, and K. Golos (editors), Proc. of the 14th Bienniel Conf. "Fracture Mechanics Beyond 2000" (ECF14) (Kraków, 2002),Vol. 2/3, EMAS, Sheffield (2002), pp. 341–346.

http: //www.sci.qut.edu.au/aemf/software.htm.

N. V. Bugai, G. V. Mukhopad, and A. Ya. Krasovskii, Elevation of the Reliability of Boilers at Power Plants [in Russian], Tekhnika, Kiev (1986).

A. B. Vainman, R. K. Melekhov, and O. D. Smiyan, Hydrogen Embrittlement of the Elements of High-Pressure Boilers [in Rus-sian], Naukova Dumka, Kiev (1990).

TU 14-3-460-75. Seamless Steel Pipes for Steam Boilers and Pipelines [in Russian], Minchermet, Moscow (1976).

K. R. Castleman, Digital Image Processing,Prentice-Hall, Englewood Cliffs, NJ (1996).

S. Ando, "Image field categorization and edge/corner detection from gradient covariance," IEEE Trans. PAMI,No. 2, 179–190 (2000).

L. Heucke, M. Knaak, and R. Orglmeister, "A new image segmentation method based on human brightness perception and foveal adaptation," IEEE Signal Proces. Lett.,7, No. 6, 129–131 (2000).

K. Karu and A. K. Jain, "Fingerprint classification," Pattern Recognition, 29, No. 3, 389–404 (1996).

M. Kawagoe and A. Tojo, "Fingerprint pattern classification," Pattern Recognition, 17, No. 3, 295–303 (1984).

D. Monro and B. Sherlock, "A model for interpreting fingerprint topology," Pattern Recognition, 26, No. 7, 1047–1055 (1993).

L. Tóth and H. Nukyforchyn, "RIMAP project-RIMAP NAS Network," Fiz.-Khim. Mekh. Mater., 38, No. 4, 136 (2002).

Rights and permissions

About this article

Cite this article

Kosarevych, R.Y., Student, O.Z., Onyshchak, Y.D. et al. Estimation of Damage to the Collector of a Water Economizer by Thermal Fatigue Cracks. Materials Science 40, 132–138 (2004). https://doi.org/10.1023/B:MASC.0000042796.06312.c9

Issue Date:

DOI: https://doi.org/10.1023/B:MASC.0000042796.06312.c9