Abstract

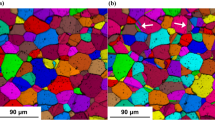

In most studies related to milled powders, the grain size1 is analyzed via X-ray diffraction (XRD) experiments, and a transmission electron microscopy (TEM) image with high magnification, if provided, is used primarily to confirm the results obtained by XRD experiments. This widely used approach is reasonable in light of the difficulties associated with TEM sample preparation. The present study, however, addresses the hypothesis that such an approach may not be valid when there is an inhomogeneous distribution of grains present. TEM examination, carried out in carefully prepared Al-7.5 wt% Mg samples, in which a global region is observable by TEM, provided the opportunity for quantitative analysis of grain size in cryomilled powders having an inhomogeneous distribution of grain sizes. The cryomilled Al-7.5 wt% Mg had a bimodal grain microstructure of 77% (area fraction) fine grains in the range of 10 to 60 nm and 23% coarse grains of approximately 1 μm. The results show that the XRD analysis yields a grain size that is close to that present in the fine-grained regions (i.e., 10–60 nm). The present study also systematically investigated the influence of the nine possible combinations of the Cauchy (C) and the Gaussian (G) approximations on the calculated grain size value, and the results show that the CC-CC approximation resulted in the largest calculated grain size, the GG-GG generated the smallest one, and the CG-CG, the approximation recommended by Klug and Alexander [1], led to a calculated grain size that is approximately equal to the average one from the CC-CC and GG-GG approximations. The maximum possible fluctuation of grain size values stemming from the various approximations is 38%.

Similar content being viewed by others

References

H. P. Klug and L. E. Alexander, "X-ray Diffraction Procedures" (John Wiley & Sons, New York, 1974) p. 634.

C. E. Krill and R. Birringer, Phil. Mag.A 77 (1998) 621.

H. G. Jiang, M. Ruhle and E. J. Lavernia, J. Mater. Res. 14 (1999) 549.

H. H. Tian and M. Atzmon, Phil. Mag.A 79 (1999) 1769.

T. Ungar, S. Ott, P. G. Sanders, A. Borbely and J. R. Weertman, Acta Materialia 46 (1998) 3693.

C. Suryanarayana, Int. Mat. Rev. 40 (1995) 41.

J. He, M. Ice, S. Dallek and E. J. Lavernia, Metall. Mater. Trans.A 31A (2000) 541.

J. He, M. Ice and E. J. Lavernia, ibid. 31A (2000) 555.

J. He and J. M. Schoenung, ibid. 34A (2003) 673.

Idem., Mater. Sci. Eng.A 336 (2002) 274.

J. He and E. J. Lavernia, J. Mater. Res. 16 (2001) 2724.

J. S. Benjamin, Metall. Trans. 1 (1970) 2943.

V. L. Tellkamp, A. Melmed and E. J. Lavernia, Metall. Mater. Trans.A 32A (2001) 2335.

D. Witkin, Z. Lee, R. Rodriguez, S. Nutt and E. J. Lavernia, "Bulk Nanostructured Al-Mg Alloy for High Strength and Increased Ductility," Scripta Materialia, accepted, 2003.

Y. M. Wang, M. W. Chen, F. H. Zhou and E. Ma, Nature 419(6910) (2002) 912.

J. He, K. H. Chung, X. Liao, Y. T. Zhu and E. J. Lavernia, Metall. Mater. Trans.A 34 (2003) 707.

Zonghoon Lee, Rodolfo Rodriguez, Robert W. Hayes, Enrique J. Lavernia and Steven R. Nutt, "Microstructural Evolution and Deformation of Cryomilled Nanocrystalline Al-Ti-Cu alloy," submitted to Acta Meter. 2003.

B. D. Cullity, in "Elements of X-ray Diffraction," 2nd ed. (Addison-Wesley Publishing Company, Inc., Reading, MA, 1978) p. 134, 292, 512.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

He, J., Ye, J., Lavernia, E.J. et al. Quantitative analysis of grain size in bimodal powders by x-ray diffraction and transmission electron microscopy. Journal of Materials Science 39, 6957–6964 (2004). https://doi.org/10.1023/B:JMSC.0000047538.95825.ad

Issue Date:

DOI: https://doi.org/10.1023/B:JMSC.0000047538.95825.ad