Abstract

Surface preparation of substrates is a major stage in thermal spraying as it greatly influences coating adhesion. Standard grit-blasting creates roughness but also often leaves grit inclusions at the substrate surface, which are detrimental for coating quality. In contrast, the use of smooth substrates involves improvements in metallurgical adhesion.

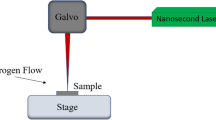

This work deals with the use of substrate pre-heating and of the PROTAL® process (‘PROjection Thermique Assistée par Laser’) to promote metallurgical adhesion. PROTAL is based on substrate laser treatment prior to spraying to achieve an oxide-free interface and, under specific conditions, which modifies the substrate morphology. A metallurgically reactive system (i.e., copper sprayed onto Al 2017) was selected to be suitable for controlling metallurgical features at the coating-substrate interface (mainly pores, intermetallic phases and pre-existing cracks). These were shown to depend on substrate roughness and on the substrate temperature during the first spraying pass.

LAser shock adhesion test, namely LASAT, was developed to enable morphological and metallurgical features of as-sprayed interfaces to be studied separately. The existence of a critical roughness for anchoring (CRA) and of an adhesion transition temperature (ATT) could be assumed. As for metallurgical properties, interface intermetallics and pre-existing cracks were shown to be detrimental for adhesion. Moreover, LASATesting succeeded in showing that adhesion of PROTAL coatings is better than that of APS-only coatings.

Similar content being viewed by others

References

N. Iwamoto et al., The Effect of Pretreatments of Metals on Bond Adhesion, Int. Thermal Spray Conference “ITSC 1983,” Essen (1983) p. 18.

X. Q. Ma, F. Borit, V. Guipont and M. Jeandin J. Adv. Mater. 34 (2002) 52.

D. Cook, M. Zaluzec and K. Kowalsky, Development of Thermal Spray for Automotive Cylinder Bores, Int. Thermal Spray Conference “ITSC 2003,” Orlando, edited by C. Moreau and B. Marple (ASM Int., Materials Park, OH, USA, 2003) p. 143.

C Coddet et al., J. Therm. Spray Techn. 8(2) (1999) 235.

F. Folio, J. Michler and G. Barbezat Surf. Eng. 17(6) (2001) 490.

J. Haynes and J. Karthikeyan, Cold Spray Copper Application for Upper Stage for Upper Rocket Design, Int. Thermal Spray Conference “ITSC 2003,” Orlando, edited by C. Moreau and B. Marple (ASM Int., Materials Park, OH, USA, 2003) p. 79.

C. Bolis et al., “Developments in Laser Shock Adhesion Test (LASAT), Int. Thermal Spray Conference “ITSC 2002,” Essen, edited by E. Lugsheider et al. (ASM Int., Materials Park, OH, USA, 2002) p. 587.

M. Boustie et al., Europ. Phys. J. AP5 (1999) 149.

S. Barradas et al., Study of the Role of (Cu, Al) Intermetallics on Adhesion of Copper Plasma-Sprayed onto Aluminum using LAser Shock Adhesion Testing (LASAT), Int. Thermal Spray Conference “ITSC 2002,” Essen, edited by E. Lugsheider et al. (ASM Int., Materials Park, OH, USA, 2002) p. 592.

D. Bouchard et al., Metall. Mater. Trans. B. 32B (2001) 111.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Barradas, S., Jeandin, M., Bolis, C. et al. Study of adhesion of PROTAL® copper coating of Al 2017 using the laser shock adhesion test (LASAT). Journal of Materials Science 39, 2707–2716 (2004). https://doi.org/10.1023/B:JMSC.0000021445.74736.b3

Issue Date:

DOI: https://doi.org/10.1023/B:JMSC.0000021445.74736.b3