Abstract

The strains in an Al2O3/NiCr coating, which was thermally sprayed on SUS304 steel, were analyzed using an electronic speckle pattern interferometry (ESPI) system during fatigue testing (R = 0, σmax = 173 MPa) at high temperature of 873 K. The strain changes with the crack initiation in the coatings and the delamination at the coating/substrate interface are accordingly discussed.

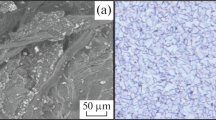

Surface cracks originated from the top coating of Al2O3 and stopped at the bond coating of NiCr after 2 cycles test at 873 K. Many surface cracks and delamination along the NiCr/substrate interface were confirmed after 1 × 105 cycles test. The strain values of un-sprayed specimens obtained from the ESPI system agreed with those measured by the strain gauge when tensile stresses were applied at room temperature. The deformation by thermal expansion and stress application at high temperatures can also be easily measured using this method. The strain on sprayed specimens was almost the same with that on un-sprayed specimens at 873 K, indicating the deformation in the coatings are always associated with that of the substrate surfaces at high temperature. By comparing and analyzing the strain distribution on the coating surface, the presence of cracks in the coatings and delamination at the coating/substrate interface can be in-situ and nondestructively detected.

Similar content being viewed by others

References

K. Kojima, J. Surf. Finish. Soc. Jpn. 41 (1990) 988.

M. Kido, R. Wang, S. Nakamura, M. Takeda, M. Yamazaki and T. Tokuda, J. Soc. Mater. Sci. Jpn. 51 (2002) 1417.

I. Nishikawa, K. Ogura, M. Yamagami and K. Kuwayama, ibid. 43 (1994) 1290.

H. Waki, K. Ogura and I. Nishikawa, JSME Intern. J. Series A 44 (2001) 374.

5H. Waki, M. Nishii, K. Ogura and I. Nishikawa, ibid. 66 (2000) 1520.

H. Waki, K. Ogura, I. Nishikawa, H. Nagamura and M. Nishii, ibid. 66 (2001) 1148.

A. Ibrahim and C. C. Berndt, J. Mater. Sci. 33 (1998) 3095.

Y. Itoh, M. Satoh, Y. Harada and J. Takeuchi, J. Soc. Mater. Sci. Jpn. 44 (1995) 1361.

M. Takeda, T. Okabe, M. Kido and Y. Harada, J. Jpn. Therm. Spray. Soc. 38 (2001) 58.

T. Shiraishi, H. Ogiyama, H. Tsukuda and Y. Soyama, J. Hig. Tem. Soc. 17 (1991) 34.

11T. Ogawa, J. Jpn. Therm. Spray. Soc. 35 (1998) 307.

M. Ohki, T. Hwu, Y. Mutoh, H. Kita and Y. Unno, ibid. 36 (1999) 12.

J. Oh, J. Komotori and M. Shimizu, ibid. 37 (2000) 166.

J. Hwang, T. Ogawa, K. Tokaji, T. Ejima, Y. Hobayashi and Y. Harada, J. Soc. Mater. Sci. Jpn. 45 (1996) 927.

H. Suzuki, T. Ueki and M. Fukumaoto, Trans. Jpn. Soc. Mech. Eng. Series A 57 (1991) 1062.

D. Zhang, M. Kato and K. Nakasa, J. Soc. Mater. Sci. Jpn. 48 (1999) 1065.

A. J. Moore and J. R. Tyrer, J. Strain Analysis 29 (1994) 257.

S. Toyooka, Mater. Techn. 70 (2000) 869.

K. Kim and M. Murozono, Trans. Jpn. Soc. Mech. Eng, Series A 60 (1994) 2567.

S. Dilhaire, S. Jorez, A. Cornet, E. Schaub and W. Claeys, Microelectr Reliab. 39 (1999) 981.

T. Torii, K. Honda, T. Fujibayashi and T. Hatano, Trans. Jpn. Soc. Mech. Eng. Series A 55 (1989) 1525.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, R., Kido, M. Using ESPI system to measure high temperature fatigue deformation of ceramics thermally sprayed SUS304 steel. Journal of Materials Science 39, 1389–1395 (2004). https://doi.org/10.1023/B:JMSC.0000013902.30089.1f

Issue Date:

DOI: https://doi.org/10.1023/B:JMSC.0000013902.30089.1f