Abstract

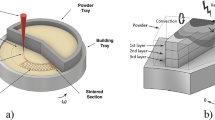

This paper reports on the density of cubic primitives made by Direct Metal Laser Re-Melting, a process variant of selective laser sintering (SLS). Here, stainless steel 316L powder fractions are scanned and fused by a 90 W Nd:YAG laser in consecutive 100 μm layers in order to build a 3-Dimensional object. The effects of Q-Switch pulsing frequency, scanning speed and scan spacing on sample density are described. The samples are measured by two methods: a weight/volume analysis and a xylene impregnation technique. The results are supported by microscopy analysis for qualitative arguments. The results show the significant influence of pulsing the beam on the density of the fabricated material. Also reported is the relationship of material density with energy density (as a function of the process parameters; power, scan speed and scan spacing). Optical analysis of material cross sections shows a periodic occurrence of porosity across the whole range of samples. Causes for this are discussed.

Similar content being viewed by others

References

N. Hopkinson and P. Dickens, Rapid Prototyping Journal 7(4) (2001).

K. W. Dalgarno, T. H. C. Childs, I. Rowntree and R. Rothwell, “Finite Element Analysis of Curl Development in the Selective Laser Sintering Process,” Proc. Solid Freeform Fabrication Symposium (University of Texas at Austin, TX, 1996) Vol. 7.

W. M. Steen, “Laser Material Processing” (Springer Verlag, 1991).

V. Svetsov, M. Popova, V. Rybakov, V. Artemiev and S. Medveduk, Shock Waves 7 (1997).

R. Morgan, C. J. Sutcliffe and W. O'Neill, Rapid Prototyping Journal 7(3) (2001).

“ASM Metals Reference Book,” 3rd ed. (ASM International, Ohio, USA, 1993).

W. Meiners, K. Wissenbach and R. Propawe, “Direct Selective Laser Sintering of Steel Powder,” Proc. Laser Assisted Net shape Engineering (LANE, 1997) Vol. 2.

S. Katayama, N. Seto, M. Mizutani and A. Matsunawa, “Formation Mechanism of Porosity in High Power YAG Laser Welding,” Proc. ICALEO 2000, Section C, p. 6.

G. Arthur, J. Inst. Met. 83 (1954–55) 329.

J. J. Beaman, J. W. Barlow, D. L. Bourell, R. H. Crawford, H. L. Marcus and K. P. Mcalea, “Solid Freeform Fabrication: A New Direction in Manufacturing” (Kluwer Academic Publishers, 1997).

S. Kraupl and P. Hoffman, “New Developments for Laser Sintering of Metallic Powders,” Proc. Laser Assisted Net Shape Engineering (LANE, 1997) Vol. 2.

R. H. Morgan, A. Papworth, C. J. Sutcliffe, P. Fox and W. O'Neill, “Direct Metal Laser Re-Melting of 316L Stainless Steel Powder. Part 1: Analysis of Thin Wall Structures,” Proc. Solid Freeform Fabrication Symposium (University of Texas at Austin, TX, 2001) Vol. 12.

R. M. German, “Sintering Theory and Practice” (Wiley Interscience Publications, 1994).

R. H. Morgan, A. Papworth, C. J. Sutcliffe, P. Fox and W. O'Neill, J. Mater. Sci. 37(15) (2002).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Morgan, R., Sutcliffe, C.J. & O'Neill, W. Density analysis of direct metal laser re-melted 316L stainless steel cubic primitives. Journal of Materials Science 39, 1195–1205 (2004). https://doi.org/10.1023/B:JMSC.0000013875.62536.fa

Issue Date:

DOI: https://doi.org/10.1023/B:JMSC.0000013875.62536.fa