Abstract

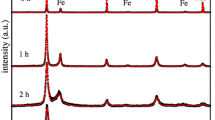

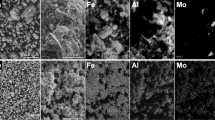

Mechanical alloying of immiscible elements in the Fe–Mg system (≤32 at % Mg) is achieved by grinding in a planetary ball mill. The process is studied by x-ray diffraction, Mössbauer spectroscopy, and magnetic measurements. The results attest to the formation of supersaturated solid solutions of Mg in α-Fe. The highest Mg content of the solid solutions is 5–7 at %. Mössbauer results are used to evaluate the changes in the hyperfine magnetic field at Fe nuclei associated with the presence of one Mg atom among the nearest neighbors and next nearest neighbors of Fe in the solid solutions: ΔH 1 = –1760 kA/m and ΔH 2 = –800 kA/m, respectively. Increasing the Mg content of the starting mixture reduces Mg solubility in Fe. Thermodynamic analysis indicates that the driving force for the formation of solid solutions may be associated with the excess energy of coherent interfaces in the Fe–Mg nanocomposite resulting from mechanical alloying. The elastic strain arising from the lattice mismatch between Fe and Mg facilitates incorporation of Mg into α-Fe. Above a certain Mg content, no coherent interfaces are formed, and the thermodynamic driving force for Mg dissolution disappears. As a result, the system becomes immiscible.

Similar content being viewed by others

REFERENCES

Suryanarayana, C., Mechanical Alloying and Milling, Prog.Mater.Sci., 2001, vol. 46, pp. 1–184.

Khodakov, G.S., Fizika izmel'cheniya (Physics of Milling), Moscow: Nauka, 1972.

Kuznetsov, V.A., Lipson, A.G., and Sakov, D.M., On the Limit of Crystal Comminution, Zh.Fiz.Khim., 1993, vol. 67, no. 4, pp. 782–786.

Dorofeev, G.A., Ul'yanov, A.L., Konygin, G.N., and Elsukov, E.P., Comparative Analysis of the Mechanisms, Thermodynamics, and Kinetics of Mechanical Alloying in the Systems Fe(68)M(32) (M = Si, Sn), Fiz.Met.Metalloved., 2001, vol. 91, no. 1, pp. 47–55.

Elsukov, E.P., Dorofeev, G.A., Fomin, V.M., et al., Mechanically Alloyed Fe(100 – x)C(x) (x = 5–25) Powders: I. Structure, Phase Composition, and Thermal Stability, Fiz.Met.Metalloved., 2002, vol. 94, no. 4, pp. 35–364.

Elsukov, E.P., Dorofeev, G.A., Ul'yanov, A.L., et al., Solid-State Reactions in the Fe(68)Ge(32) System during Mechanical Alloying, Fiz.Met.Metalloved., 2003, vol. 95, no. 2, pp. 164–169.

Yavari, A.R., Desré, P.J., and Benameur, T., Mechanically Driven Alloying of Immiscible Elements, Phys.Rev.Lett., 1992, vol. 58, no. 14, pp. 2235–2238.

Badmos, A.K. and Bhadeshia, H.K.D.H., The Evolution of Solutions: A Thermodynamic Analysis of Mechanical Alloying, Metall.Mater.Trans.A., 1997, vol. 28, pp. 2189–2194.

Dorofeev, G.A., Yelsukov, E.P., Ulyanov, A.L., and Konygin, G.N., Thermodynamic Simulation of Mechanically Alloyed Solid Solution Formation in Fe–Sn System, Mater.Sci.Forum, 2000, vols. 343–346, pp. 58–590.

Gente, C., Oehring, M., and Bormann, R., Formation of Thermodynamically Unstable Solid Solutions in the Cu– Co System by Mechanical Alloying, Phys.Rev.B: Condens.Matter, 1993, vol. 48, no. 18, pp. 13244–13252.

Bai, H.Y., Michaelsen, C., Gente, C., and Bormann, R., Amorphization by Mechanical Alloying in Metallic System with Positive Gibbs Energy of Formation, Phys.Rev.B: Condens.Matter, 2002, vol. 63, p. 064202-1-10.

Ishida, Y., Ichinose, H., Kizuka, T., and Suenada, K., High-Resolution Microscopy of Interfaces in Nanocrystalline Materials, Nanostruct.Mater., 1995, vol. 6, pp. 115–124.

Ivchenko, V.A., Uimin, M.A., Yermakov, A.Ye., and Korobeinikov, A.Yu., Atomic Structure and Magnetic Properties of Cu 80 Co20 Nanocrystalline Compound Produced by Mechanical Alloying, Surf.Sci., 1999, vol. 440, pp. 420–428.

Gerasimov, K.B., Mytnichenko, S.V., Pavlov, S.V., et al., Structural Study of Mechanically Alloyed Cu30 Cr70 by Anomalous X-ray Diffraction and EXAFS-Spectros-copy, J.Alloys Compd., 1997, vol. 252, pp. 179–183.

Tie, L., Yu-zhi, L., and Yu-beng, Z., Hyperfine Magnetic Field in Mechanically Alloyed Fe–Cu, Phys.Rev.B: Condens.Matter, 1995, vol. 52, no. 2, pp. 1120–1122.

Huang, J.Y., Jiang, J.Z., Yasuda, H., and Mori, H., Kinetic Process of Mechanical Alloying in Fe 50 Cu 50, Phys.Rev.B: Condens.Matter, 1998, vol. 58, no. 18, pp. R11817–R11820.

Kaloshkin, S.D., Tomilin, I.A., Andrianov, G.A., et al., Phase Transformations and Hyperfine Interactions in Mechanically Alloyed Fe–Cu Solid Solutions, Mater.Sci.Forum, 1997, vols. 235–238, pp. 565–570.

Ma, E., He, J.-H., and Schilling, P.J., Mechanical Alloying of Immiscible Elements: Ag–Fe Contrasted with Cu– Fe, Phys.Rev.B: Condens.Matter, 1997, vol. 55, no. 9, pp. 5542–5545.

Klassen, T., Herr, U., and Averback, R.S., Ball Milling of Systems with Positive Heat of Mixing: Effect of Temperature in Ag–Cu, Acta Mater., 1997, vol. 45, no. 7, pp. 2921–2930.

Ivchenko, V.A., Wanderka, N., Czubayko, U., et al., Mechanically Alloyed Nanocrystalline Cu 80 Co 20 Investigated by AP/FIM and 3DAP, Mater.Sci.Forum, 2000, vols. 343–346, pp. 709–714.

Kubaschewski, O., Iron—Binary Phase Diagrams, Berlin: Springer, 1982. Translated under the title Diagrammy sostoyaniya dvoinykh sistem na osnove zheleza, Moscow: Metallurgiya, 1985.

De Boer, F.R., Boom, R., Mattens, W.C.M., et al., Cohesion in Metals, vol. 1: Transition Metal Alloys, Amsterdam: Elsevier, 1988.

Hightiwer, A., Fultz, B., and Bowman, R.C., Mechanical Alloying of Fe and Mg, J.Alloys Compd., 1997, vol. 252, pp. 238–244.

Voronina, E.V., Ershov, N.V., Ageev, A.L., et al., Regular Algorithm for the Solution of the Inverse Problem in Mössbauer Spectroscopy, Phys.Status Solidi B, 1990, vol. 160, pp. 625–634.

Reuther, H., Betzl, M., Matz, W., and Richter, E., Alloying by High Ion Implantation of Iron into Magnesium and Aluminium, Hyperfine Interact., 1998, vol. 113, pp. 391–401.

Hirth, J.P. and Lothe, J., Theory of Dislocations, New York: McGraw-Hill, 1968. Translated under the title Teoriya dislokatsii, Moscow: Atomizdat, 1972.

Hirth, J.P. and Feng, X., Critical Layer Thickness for Misfit Dislocation Stability in Multilayer Structures, J.Appl.Phys., 1990, vol. 67, no. 7, pp. 3343–3349.

MacPherson, G., Beanland, R., and Goodhew, P.J., On the Development of Misfit Dislocation Distributions in Strained Epitaxial Layer Interfaces, Scr.Metall.Mater., 1995, vol. 33, pp. 123–128.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Dorofeev, G.A., Elsukov, E.P. & Ul'yanov, A.L. Mechanical Alloying of Immiscible Elements in the Fe–Mg System. Inorganic Materials 40, 690–699 (2004). https://doi.org/10.1023/B:INMA.0000034767.14276.a9

Issue Date:

DOI: https://doi.org/10.1023/B:INMA.0000034767.14276.a9