Abstract

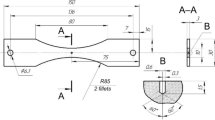

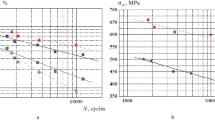

In this paper, the result from rotating bending fatigue tests of notched specimens are carried out on aluminum cast alloys and high strength steels with H B≃600 are reported. The threshold stress intensity factor range under a stress controlled condition, ΔK w, is introduced for the purpose of predicting the fatigue limit of a metal with an arbitrary crack. The ΔK w value of a long crack, ΔK wUL, is obtained from the fatigue crack propagation limit σw2 of specimens with a sharp and deep notch; ΔK w increases with crack length, and ΔK wUL is an upper limit of ΔK w. Since there are few σw2 data of steels with H B≥400, the σw2 values are evaluated by the fatigue crack initiation limit predicted using Linear Notch Mechanics and the relation between σw1 and σw2 at the branch point. Using ΔK wUL values of many metals with a long crack, the ΔK wUL values are approximated with a simple formula. Moreover the lower limit value of ΔK w versus the crack length, ΔK wLL, is proposed. Then using the ΔK w and ΔK wUL formulae and the ΔK wLL value, the smallness of a fatigue crack is clarified.

Similar content being viewed by others

References

ASTM (1979). Proposed Method of Test for Measurement of Fatigue Crack Growth Rates. American Society for Testing and Material, E24-04-03.

Benthem, J.P. and Koiter, W.T. (1973). Asymptotic Approximations to Crack Problems, in Mechanics of Fracture 1. Noordhoff, 131–178.

Chen, D.H. and Nisitani, H. (1988). Analysis of plasticity-induced crack closure by the extended body force method (Comparison of various analyitical results based on Dugdale hypothesis. JSME International Journal, Series I, 31-3, 136–153.

Dugdale, D.S. (1960). Yielding of steel sheets containing slits. Journal of the Mechanics and Physics of Solids 8, 100–104.

Elber, W. (1971). The signification of fatigue crack closure, damage tolerance in aircraft structure. American Society for Testing and Material, Special Technical Publication 486, 230–242.

Isibasi, T. (1954). Prevention of Fatigue and Fracture of Metals, (in Japanese), Yokendo.

Jono, M., Song, J., Mikami, S. and Ogaki, M. (1984). Fatigue crack growth and crack closure behavior of structural materials. Journal of the Society of Material Science, Japan 33-367, 468–474.

Kawagoishi, N., Nisitani, H., Toyohiro, T. and Kamifukumoto, H. (1993). Effect of microstructure on the fatigue notch sensitivity in DP steel. Transactions of the Japan Society of Mechanical Engineers, (in Japanese), A59-559, 752–756.

Kawagoishi, N., Nisitani, H. and Tuno, T. (1990). Notch sensitivity of squeeze cast aluminum alloy in rotating bending fatigue. Transactions of the Japan Society of Mechanical Engineers, (in Japanese), A56-521, 10–14.

Kitsunai, Y. (1980). Effect of microstructure on fatigue crack growth mechanism in high strength steel (Relationship between crack growth rate and prior austenite grain size). Journal of the Society of Material Science, Japan 29-323, 795–800.

Klesnil, M. and Lukas, P. (1972). Effect of stress cycle asymmetry on fatigue crack growth. Engineering Fracture Mechanics 9, 231–240.

Laird, C. (1967). Influence of metallurgical structure on the mechanisms of fatigue crack propagation. American Society for Testing and Material, Special Technical Publication 415, 131–168.

Meyn, D.A. (1968). Observations on micromechanisms of fatigue crack propagation in 2024 aluminum. ASM 61, 42–51.

Minagawa, K., Matsuo, Y. and McEvily, A. J. (1982). The influence of a duplex microstructure in steels on fatigue crack growth in the near-threshold region. Metallurgical Transactions A 13A, 439–445.

Miller, K. (1999). A historical perspective of the important parameters of metal fatigue: and problem for the next century. Proceedings of 7th International Fatigue Congress, EMAS, 15–39.

Mura, T. and Weertman, J. (1983). Fatigue crack growth threshold concepts. EMAS, 531–549.

Murakami, Y. (2002). Metal Fatigue: Effects of Small Defects and Nonmetallic Inclusions, Elsevier.

Murakami, Y. and Endo, M. (1983). Quantitative evaluation of fatigue strength of metals containing various small defects on cracks. Engneering Fracture Mechanics 17, 1–15.

Nakai, Y., Tanaka, K. and Kawashima, R. (1983). Propagation and non-propagation of fatigue cracks in notched plates of low-carbon steel. Journal of the Society of Material Science, Japan 32-356, 535–541.

National Reseach Institute for Materials (1995). Fundamental fatigue properties of hard steels. NRIM Material Strength Data Sheet, Technical Document, No. 9.

Nisitani, H. (1968). Effects of size on the fatigue limit and the branch point in rotary bending tests of carbon steel. Bulletin of the Japan Society of Mechanical Engineers 11(48), 947–957.

Nisitani, H. (1972). Correlation between notch sensitivity of a material and its non-propagating crack, under rotating bending stress. Proceedings of the 1971 International Conference on Mechanical Behavior of Materials, Vol. II, 312–322.

Nisitani, H. (1994). Linear crack mechanics and linear notch mechanics in computational and experimental fracture mechanics. Computational Mechanics Publication, 187–211.

Nisitani, H. and Chishiro, I. (1974). Non-propagating micro-cracks of plain specimens and fatigue notch sensitivity in annealed or heat-treated 0.5% C steel. Transactions of the Japan Society of Mechanical Engineers, (in Japanese), A40-329, 41–52.

Nisitani, H. and Endo, M. (1988). Unified treatment of deep and shallow notches in rotating bending fatigue. American Society for Testing and Material, Special Technical Publication 924(1), 136–153.

Nisitani, H. and Kawagoishi, N. (1985). Comparison of notch sensitivities in three age-hardened aluminum alloys. Transactions of the Japan Society of Mechanical Engineers, (in Japanese), A51-462, 530–562.

Nisitani, H. and Nisida, S. (1970). Change in surface states and incipient fatigue cracks in electro-polished low carbon steel (plain and notched specimens) under rotating bending stress. Bulletin of the Japan Society of Mechanical Engineers 13(62), 961–967.

Nisitani, H. and Nisida, S. (1970). Change in surface states of electropolished S10C, S30C and S50C steel specimens (plain and notched) under rotating bending stress. The Japanese Society for Strength and Fracture of Materials, (in Japanese), 5-3, 84–97.

Nisitani, H., Noguchi, H., Uchihori, H. and Nakae, H. (1989). A examination of the notch effect in fatigue of carbon steels by linear notch mechanics. International Journal of the Japan Society of Mechanical Engineers, Series I 32(3), 439–449.

Nisitani, H. and Okasaka, K. (1973). Effect of Mean stress on fatigue strength, crack strength and notch radius at branch point in axial fatigue of 7:3 brass. Bulletin of the Japan Society of Mechanical Engineers 16(99), 1229–1238.

Noda, N., Takase, Y and Kanzaki, K. (1999). Stress concentration formula useful for any shape of notch in a round test specimen under tension and under rotating bending. Fatigue and Fracture of Engineering Materials and Structures 22, 1071–1082.

Noguchi, H. and Aono, Y. (1995). Application limit of linear notch mechanics. Transactions of the Japan Society of Mechanical Engineers, (in Japanese), A61-589, 2044–2051.

Noguchi, H., Nisitani, H., Kim, Y.H. and Nishizawa, A. (1992). Fatigue characteristics of plain and notched specimens of SiC-Whisker-reinforced aluminum alloy in comparison with alminum alloy. Transactions of the Japan Society of Mechanical Engineers, (in Japanese), A58-554, 1765–1784.

Oda, Y., Furuya, Y., Noguchi, H. and Higashida, K. (2002). AFM and SEM observation on mechanism of fatigue crack growth in a Fe-3.2% Si single crystal. International Journal of Fracture 113, 213–231.

Oyama, A. and Tange, A. (1984). Transactions of the Japan Society for Spring Research 29, 30–38.

Ritchie, R.O., Suresh, S. and Moss, C.M. (1980). Near-threshold fatigue crack growth in a 2 1/4 Cr-Mo pressure vessel steel in air and hydrogen. Journal of Engineering Materials and Technology, ASME, Series H. 102(3), 293–299.

Sugiyama, Y., Asami, K. and Matsuoka, S. (1992). Quatitative evaluation method of fatigue limit of materials with defects and its investigation using ductile cast iron. Transactions of the Japan Society of Mechanical Engineers A58-556, 2287–2292.

Suresh, S., Zimiski, G.F. and Ritchie, R.O. (1981). Oxide-induced crack closure: An explanation for near-threshold corrosion fatigue crack growth behavior. Metallurgical Transactions A 12A, 1434–1443.

Takao, K., Nisitani, H. and Sakaguchi, H. (1980). Relation between crack initiation process and notch sensitivity in rotating bending fatigue. Journal of the Society of Material Science, Japan, (in Japanese) 29-325, 982–987.

Tanaka, K. and Nakai, Y. (1984). Prediction of fatigue threshold of notched components. Transaction of ASME, Journal of Engineering Technology 106, 192–199.

Tanaka, K., Nakai, Y. and Kawashima, R. (1984). Stress-ratio effect on fatigue crack growth threshold in steels. Journal of the Society of Material Science, Japan 33-371, 1045–1051.

Taylor, D. (1985). Compedium of fracture thresholds and growth rates. EMAS.

Vosikovsky, O. (1979). The effect of stress ratio on fatigue crack growth rates. Engneering Fracture Mechanics 11, 595–602.

Yokobori, A.T. and Yokobori, T. (1981). On micro-and macro-mechanics of fatigue thresholds. EMAS, Fatigue Threshold, 171–189.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Miyazaki, T., Noguchi, H. & Ogi, K. Quantitative evaluation of the fatigue limit of a metal with an arbitrary crack under a stress controlled condition – Stress Ratio R=−1. International Journal of Fracture 129, 21–38 (2004). https://doi.org/10.1023/B:FRAC.0000038886.80094.59

Issue Date:

DOI: https://doi.org/10.1023/B:FRAC.0000038886.80094.59