Abstract

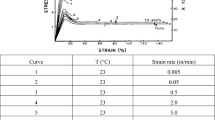

Polytetrafluoroethylene (PTFE) (Dupont Tradename Teflon) is a common polymer with many structural applications including sheet, gaskets, bearing pads, piston rings and diaphragms. The interest here developed because this polymer is being considered as the major component of a newly proposed `reactive' material with a possible application as a projectile to replace common inertial projectiles. Little mechanical property data is available on this material since it is commonly used only as a coating material with the dominant properties being its low friction coefficient and high application temperature. Previous work (Joyce, 2003) on commercially available sheet PTFE material has demonstrated the applicability of the normalization method of ASTM E1820 (1999), the elastic-plastic fracture toughness standard to develop fracture toughness properties of this material over a range of test temperatures and loading rates. Additional work on the aluminum filled `reactive' derivative of the basic PTFE polymer (Joyce and Joyce, 2004) has also recently been completed. In this work, standard ASTM E1820 fracture toughness specimens machined from sintered pucks of PTFE were tested at four test temperatures and at a range of test rates to determine the J Ic and J resistance curve characteristics of the PTFE material. The major results are that while crack extension is difficult at standard laboratory loading rates at ambient (21 °C) temperature or above, for temperatures slightly below ambient or for elevated loading rates, a rapid degradation of fracture resistance occurs and cracking occurs in a ductile or even nearly brittle manner.

Similar content being viewed by others

References

ASTME1820 (1999). Standard Test Method for Measurement of Fracture Toughness, American Society of Testing and Materials, Annual Book of ASTM Standards, Vol. 3.01.

ASTM E1221 (1996). Standard Test Method for Determining Plane-Strain Crack Arrest Fracture Toughness, KIa, of Ferritic Steels, American Society of Testing and Materials, Annual Book of ASTM Standards, Vol. 3.01.

ASTM E813 (1987). Standard Test Method for J Ic, American Society of Testing and Materials, Annual Book of ASTM Standards, Vol. 3.01.

Bernal, C.R, Cassanelli, Anibal N. and Frontini, P.M. (1985). A simple method for J-R curve determination in ABS polymers. Polymer Testing 14, 85–96.

Bernal, C.R., Cassanelli, A. and Frontini, P. (1996). On the applicability of the load separation criterion to acrylonitrile/butadiene/styrene terpolymer resins. Polymer 37, 4033–4039.

Bernal, C.R., Montemartini, P.E. and Frontini, P.M. (1996). The use of load seperation criterion and normalization method in ductile fracture characterization of thermoplastic polymers. Journal of Polymer Science 34, 1869–1880.

Chan, M.G.V. and Williams, J.G. (1983). J-integral studies of crack initiation of a tough high density polyethylene. International Journal of Fracture 23, 145–159.

Che, M., Grellman, W., Seidler, S. and Landes, J.D. (1997). Application of a normalization method for determining J-R curves in glassy polymer PVC at different crosshead speeds. Fatigue and Fracture of Engineering Materials 20, 119.

Chung, W.N. and Williams, J.G. (1991). Determination of J Ic for Polymers Using the Single Specimen Method, Elastic-Plastic Fracture Test Methods: The User's Experience (Second Volume), ASTM STP 1114, 320–339.

ESIS TC4 Test Protocol (1991). A Testing Protocol for Conducting J-crack Growth Resistance Curve Tests on Plastics.

Hashemi, S. and Williams, J.G. (1986). Fracture characterization of tough polymers using the J method. Polymer Engineering and Science 26, 760–767.

Huang, D.D. and Williams, J.G. (1987). J testing of toughened nylons. Journal of Materials Science 22, 2503–2508.

Huang, D.D. (1989). A comparison of multispecimen J-integral methods as applied to toughened polymers, Advances in Fracture Research 4, Seventh International Conference on Fracture, University of Houston, 2725–2732.

Joyce, J.A., Ernst, H. and Paris, P.C. (1980). Direct Evaluation of J-Resistance Curves from Load Displacement Records, Fracture Mechanics: Twelfth National Symposium, ASTM STP 700, ASTM, 222.

Joyce, J.A. (2001). Analysis of high rate round robin based on proposed annexes to ASTM E 1820. Journal of Testing and Evaluation 29, 329–351.

Joyce, J.A. (2003). Fracture toughness evaluation of polytetrafluorethylene. Polymer Engineering and Science 43, 1702–1714.

Joyce, J.A. and Joyce, P.J. (2004). Toughness Characterization of a Metal Filled Polytetrafluoroethylene Using the J-Integral, to be published in Engineering Fracture Mechanics.

Kirby, G., Garrett, R. and Dyka, C. (2003). Review of Progress in Modeling Constitutive, Damage and Fracture Behavior of PTFE Subject to Dynamic Loading, presented at International Conference on Platisticity, July 7-10, Quebec.

Landes, J.D., Zhou, Z., Lee, K. and Herrera, R. (1991). Normalization Method for Developing J-R Curves with the LMN function. Journal of Testing and Evaluation 19, 305–311.

Landes, J.D. and Zhou, Z. (1993). Application of Load Separation and Normalization Methods for Polycarbonate Materials. International Journal of Fracture 63, 383–393.

Landes, J.D., Bhambri, S.K. and Lee, K. (2003). Fracture Toughness Testing of Polymers Using Small Compact Specimens and Normalization. Journal of Testing and Evaluation 31(3), 126–132.

Sharobeam, H.M. and Landes, J.D. (1991). The Load Separation Criterion and Methodology in Ductile Fracture Mechanics. International Journal of Fracture 47, 81–104.

Takemori, M.T. and Narisawa, I. (1989). J-Integral Characterization of Impact-Modified Polymers, Advances in Fracture Research 4, Seventh International Conference on Fracture, University of Houston, 2733–2737.

Zhou, Z., Landes J.D. and Huang, D. (1994). J-R Curve with the Normalization Method for Toughened Polymers. Polymer Engineering and Science 34, 128–134.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Joyce, P.J., Joyce, J.A. Evaluation of the fracture toughness properties of polytetrafluoroethylene. International Journal of Fracture 127, 361–385 (2004). https://doi.org/10.1023/B:FRAC.0000037674.46965.fb

Issue Date:

DOI: https://doi.org/10.1023/B:FRAC.0000037674.46965.fb