Abstract

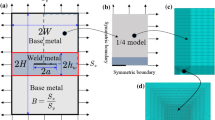

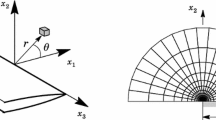

A C* integral estimation method is proposed for a crack located in the weld with a mismatch in mechanical properties from the surrounding base material. The method involves the definition of an equivalent stress-creep strain rate (ESCSR) relationship based on the mechanical properties of both the weld and base materials and the geometrical dimension of welding seam. The value of creep fracture mechanics parameter C*, for the mismatched weldment, is then estimated using the proposed ESCSR in conjunction with the reference stress (RS) method where the reference stress is defined based on the plastic limit load and the GE/EPRI estimation scheme. Referring to the equivalent stress-plastic strain (ESPS) curve in R6 and SINTAP procedures, an approximate solution for the ESCSR relationship has been obtained. Detailed formulae for the compact tension (CT) specimens have been derived on the basis of limit load solutions. Nonlinear finite element analysis of 48 cases with various degrees of mismatch in creep behaviour and different dimension of welding seam has been performed for CT specimens. Overall good agreement between the ESCSR method and the FE results provides confidence in the use of the proposed method in practice.

Similar content being viewed by others

References

ABAQUS User's Manual, (1996). Version 5.6, Hibbit, Karlsson & Sorensen.

Ainsworth, R.A. (1984). The assessment of defects in structures of strain hardening materials. Engineering Fracture Mechanics 19, 633–642.

Andersson, P., Segle, P. and Samuelson, L.A. (2000). Numerical investigation of creep crack growth in crossweld CT specimens. Part II: influence of specimen size. Fatigue and Fracture of Engineering Materials and Structures 23, 533–540.

Assire, A., Michel, B. and Raous, M. (2001). Creep crack initiation and creep crack growth assessments in welded structures. Nuclear Engineering and Design 206, 45–56.

Budden, P.J. and Curbishley, I. (2000). Assessment of creep crack growth in dissimilar metal welds. Nuclear Engineering and Design 197, 13–23.

Dogan, B. and Petrovski, B. (2001). Creep crack growth of high temperature weldments. International Journal Pressure Vessel and Piping 78, 795–805.

Kim, Y.-J., Kocak, M., Ainsworth, R.A. and Zerbst, U. (2000). SINTAP defect assessment procedure for strength mismatched structures. Engineering Fracture Mechanics 67, 529–546.

Kim, Y.-J. and Schwalbe, K.-H. (2001). Compendium of yield load solutions for strength mismatched DE(T), SE(B) and C(T) specimens. Engineering Fracture Mechanics 68, 1137–1151.

Kim, Y.-J, Kim, J.S., Huh, N.S. and Kim, Y.J. (2002). Engineering C-integral estimates for generalized creep behaviour and finite element validation. International Journal Pressure Vessel and Piping 79, 427–443.

Kim, Y.-J., Huh, N.S. and Kim, Y.J. (2001). Enhanced reference stress-based J and crack opening displacement estimation method for leak-before-break analysis and comparison with GE/EPRI method. Fatigue and Fracture of Engineering Materials and Structures 24, 243–254.

Kumar, V. and German, M.D. (1988). Elastic-plastic fracture analysis of through-wall and surface flaws in cylinders. EPRI Report, NP-5596.

Kumar, V., German, D. and Shih, C.F. (1981). An engineering approach for elastic-plastic fracture analysis. EPRI final report NP 1931.

Kumar, V. (1982). Estimation technique for the prediction of elastic-plastic fracture of structural components of nuclear systems. 6th Semi-annual reports to EPRI.

Lei, Y., Li, P. andWang, Z. (1994). A new J integral estimation method for defects in materials with non-Ramberg-Osgood stress-strain relationship. East China University of Science and Technology Report for Project 85-924-02-02.

Lei, Y. and Ainsworth, R.A. (1997). A J integral estimation method for cracks in welds with mismatched mechanical properties. International Journal Pressure Vessel and Piping 70, 237–245.

R6. (2000). Assessment of the integrity of structures containing defects, Procedure R6-Revision 4, Gloucester, UK: Nuclear Electric Ltd.

Segle, P., Andersson, P. and Samuelson, L.A. (2000). Numerical investigation of creep crack growth in cross-weld CT specimens. Part I: influence of mismatch in creep deformation properties and notch tip location. Fatigue and Fracture of Engineering Materials and Structures 23, 521–531.

Tu, S.T. (2002). Creep behavior of crack near bi-material interface characterized by integral parameters.Theoretical and Applied Fracture Mechanics 38, 203–209.

Tu, S.T. and Yoon, K.B. (1999). The influence of material mismatch on the evaluation of time-dependent fracture mechanics parameters. Engineering Fracture Mechanics 64, 765–780.

Yoon, K.B. and Kim, K.Y. (1999). High temperature fracture parameter for a weld interface crack. Theoretical and Applied Fracture Mechanics 32, 27–35.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Xuan, FZ., Tu, ST. & Wang, Z. C* estimation for cracks in mismatched welds and finite element validation. International Journal of Fracture 126, 267–280 (2004). https://doi.org/10.1023/B:FRAC.0000026578.03989.79

Issue Date:

DOI: https://doi.org/10.1023/B:FRAC.0000026578.03989.79