Abstract

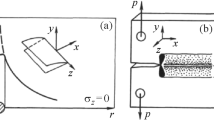

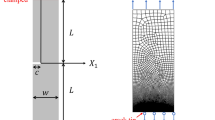

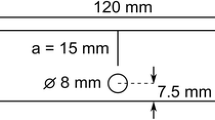

Linear elastic fracture mechanics (LEFM) integrated with the interference of fracture surface asperities has been formulated. The asperities are considered to simulate the influence of the microstructures and possibly oxide debris. The applied stress/load-crack opening displacement (COD) relationships in several cases have been derived. In the original LEFM, the stress-COD relationship is represented by a straight line passing through the origin of the stress-COD plot. The insert of one asperity results in a deviation of the stress-COD response from the LEFM relationship, leading to the exhibition of an inflection point (first contact point, σop), a larger slope, and a residual COD. In the case of two asperities, the slope and the residual COD of the stress-COD relationship become further larger, and two inflection points emerge. A general stress-COD expression in the case of multiple asperities has been derived. The slope of the stress-COD equation, the residual COD, and the minimum COD all increase with increasing number of asperities for a given loading condition, resulting in a smaller ΔCOD and Δσeff. The number of the inflection points is the same as that of the asperities. To the authors' knowledge, this paper is the first to derive analytically an applied stress-COD curve with a gradual variation below σop, caused by the asperity-/roughness-, or oxide-induced crack closure.

Similar content being viewed by others

References

Beevers, C.J., Bell, K., Carlson, R.L. and Starke, E.A. (1984). A model for fatigue crack closure. Eng. Fract. Mech. 19, 93–100.

Buck, O., Rehbein, D.K. and Thompson, R.B. (1987). Crack tip shielding by asperity contact as determined by acoustic measurements. Eng. Fract. Mech. 28, 413–424.

Carlson, R.L. and Beevers, C.J. (1984). Multiple asperity fatigue crack closure model. Eng. Fract. Mech. 20, 687–690.

Chen, D.L., Weiss, B. and Stickler, R. (1991). A new evaluation procedure for crack closure. Inter. J. Fatigue 13, 327–331.

Chen, D.L., Weiss, B. and Stickler, R. (1994). The effective fatigue threshold-significance of the loading cycle below the crack opening load. Inter. J. Fatigue 16, 485–491.

Chen, D.L., Weiss, B. and Stickler, R. (1996). A model for crack closure. Eng. Fract. Mech. 53, 493–509.

Chen, D.L. (2002). Modeling of load-COD curves in fatigue crack closure effect. In: Fatigue 2002. (Edited by A.F. Blom), Engineering Materials Advisory Services Ltd. (EMAS), West Midlands, U.K., Vol. 4, pp. 2329–2335.

Christensen, R.H. (1963). Fatigue crack growth affected by metal fragments wedged between opening-closing crack surfaces. Appl. Mater. Res. October 1963, 207–210.

Cotterell, B. (2002). The past, present, and future of fracture mechanics. Eng. Fract. Mech. 69, 533–553.

Dabayeh, A.A. and Topper, T.H. (1995). Changes in crack-opening stress after underloads and overloads in 2024-T351 aluminum alloy. Inter. J. Fatigue 17, 261–269.

Garz, R.E. and James, M.N. (1989). Observations on evaluating fatigue crack closure from compliance traces. Inter. J. Fatigue 11, 437–440.

Griffith, A.A. (1920). The phenomenon of rupture and flow in solids. Phil. Trans. Roy. Soc. London A221, 163–198.

Guvenilir, A., Breunig, T.M., Kinney, J.H. and Stock, S.R. (1997). Direct observation of crack opening as a function of applied load in the interior of a notched tensile sample of Al-Li 2090. Acta Mater. 45, 1977–1987.

Hutchinson, J.W. and Evans, A.G. (2000). Mechanics of materials: top-down approaches to fracture. Acta Mater. 48, 125–135.

Irwin, G.R. (1957). Analysis of stresses and strains near the end of a crack traversing a plate. J. Appl. Mech. 24, 361–364.

Jung, H.Y. and Antolovich, S.D. (1995). Experimental characterization of roughness-induced crack closure in Al-Li 2090 alloy. Scripta Metall. Mater. 33, 275–281.

Kardomateas, G.A. and Carlson, R.L. (1998). Predicting the effects of load ratio on the fatigue crack growth rate and fatigue threshold. Fatigue Fract. Eng. Mater. Struct. 21, 411–423.

Li, S.X., Sun, L.Z., Zang, Q.S. and Wang, Z.G. (1992). Geometric model for fatigue crack closure induced by fracture surface roughness under mode I displacements. Mater. Sci. Eng. A A150, 209–212.

Newman, J.A. and Piascik, R.S. (2002). Plasticity and roughness closure interactions near the fatigue crack growth threshold. The Thirty Third National Symposium on Fatigue and Fracture Mechanics, ASTM STP 1417, American Society for Testing and Materials, pp. 617–630.

Sanford, R.J. (2003). Principles of Fracture Mechanics, Prentice Hall/Pearson Education, Inc., Upper Saddle River, NJ.

Sehitoglu, H. and Garcia, A.M. (1997). Contact of crack surfaces during fatigue-Part 2. simulations. Metall. Mater. Trans. A 28A, 2277–2289.

Soboyejo, W.O. and Knott, J.F. (1995). Investigation of crack closure and the propagation of semi-elliptical fatigue cracks in Q1N (HY80) pressure vessel steel. Inter. J. Fatigue 17, 577–581.

Suresh, S. and Ritchie, R.O. (1982). A geometric model for fatigue crack closure induced by fracture surface roughness. Metall. Trans. A 13A, 1627–1631.

Suresh, S. and Ritchie, R.O. (1983). Some considerations on the modelling of oxide-induced fatigue crack closure using solutions for a rigid wedge inside a linear elastic crack. Scripta Metall. 17, 575–580.

Tong, F.C. and Gray, T.G.F. (1996). Fatigue crack closure study based on whole-field displacements. Inter. J. Fatigue 18, 593–601.

Vecchio, R.S., Crompton, J.S. and Hertzberg, R.W. (1986). Anomalous aspects of crack closure. Inter. J. Fract. 31, R29–R33.

Wieghardt, K. (1907). Uber das Spalten und Zerreissen elastischer Korper. Z. Mathematik und Physik 55, 60–103 (Translated by Rossmanith, H.P., 1995. On splitting and cracking of elastic bodies. Fatigue Fract. Eng. Mater. Struct. 12, 1371-1405).

Yu, X.B. and Abel, A. (2000). Crack surface interference under cyclic mode I and steady mode II loading-Part II: modeling analysis. Eng. Fract. Mech. 66, 519–535.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, D., Wang, Z. Derivation of applied stress-crack opening displacement relationships for the evaluation of effective stress intensity factor range. International Journal of Fracture 125, 371–386 (2004). https://doi.org/10.1023/B:FRAC.0000022243.38144.ce

Issue Date:

DOI: https://doi.org/10.1023/B:FRAC.0000022243.38144.ce