Abstract

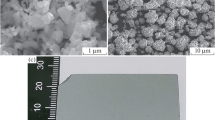

The potential use of an electrophoretic deposition method for molding preforms from a lithium alumina-silicate slip is demonstrated. The time needed to mold preforms 20 mm thick does not exceed 100 min, and their physicomechanical properties (density, porosity of green and sintered materials, mechanical strength) compare well with those of preforms obtained by the traditional ceramic technology. Slips of finely dispersed grain composition can also be used to prepare glass ceramic parts with improved physicomechanical properties.

Similar content being viewed by others

REFERENCES

E. I. Suzdal'tsev, M. A. Suslova, V. V. Vikulin, et al., RF Patent No. 2170715, MPK C04B 35_19. A Method for Molding Components from a Sintered Glass Ceramic Material of Lithium Aluminosilicate Composition [in Russian], (1999).

E. I. Suzdal'tsev, “A new direction in the synthesis of heat-resistant, radio transparent glassy crystalline materials,” Inzh. Fiz. Zh. 74(6), 131 – 135 (2001).

E. I. Suzdal'tsev, “Radio transparent, heat-resistant materials for the 21st century,” Ogneup. Tekh. Keram. No. 3, 42 – 50 (2002).

Yu. E. Pivinskii and A. G. Romashin, Quartz Ceramics [in Russian], Metallurgiya, Moscow (1974).

V. F. Tsarev, “The effect of molding parameters on properties of quartz ceramics,” Steklo Keram. No. 11, 21 – 23 (1979).

V. F. Tsarev, Yu. E. Pivinskii, and N. V. Solomin, “Electrophoretic deposition method for molding quartz ceramics,” in: Heat-resistant Inorganic Materials [in Russian], ONTI (1974), pp. 101 – 105.

N. V. Solomin, V. F. Tsarev, and Yu. E. Pivinskii, “Molding components from aqueous quartz glass suspensions by electrophoretic deposition method,” Ogneupory, No. 10, 56 – 59 (1973).

M. Aveline, “Faconnage par èlectrophorèse,” L'industrie Cèramique, No. 581, 28 – 31 (1966).

F. S. Éntelis and M. E. Sheinina, “Molding porcelain components by electrophoretic deposition method,” Steklo Keram. No. 11, 19 – 21 (1979).

I. S. Kainarskii and K. B. Malinovskii, “Electrophoresis as a method for molding fine ceramic products,” Steklo Keram. No. 4, 26 – 30 (1958).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Suzdal'tsev, E.I., Kharitonov, D.V. Potentiality of the Electrophoretic Deposition Method for Molding Components from Lithium Alumina-Silicate Glass Slips. Refractories and Industrial Ceramics 44, 215–218 (2003). https://doi.org/10.1023/A:1027323313484

Issue Date:

DOI: https://doi.org/10.1023/A:1027323313484