Abstract

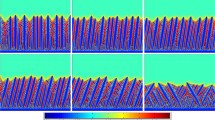

The sectorial structure of chrysoberyl crystals grown in the [100] direction by horizontal directional solidification is analyzed. A major part of such crystals is constituted by the (120) growth sector. Physical modeling of mass transport during the directional solidification of chrysoberyl suggests the existence of two stable melt flows, one circulating relatively rapidly near the free surface and the other circulating near the bottom of the container. This flow pattern is responsible for the formation of the (130) and (100) growth sectors. The inclusion-rich zone in the bottom part of the crystal is due to the slow melt circulation at the boundary between the two flows.

Similar content being viewed by others

REFERENCES

Gurov, V.V., Bukin, G.V., Yurkin, A.M., and Kovalenko, N.V., Growth of Cr-and Ti-Activated Chrysoberyl Crystals by Horizontal Directional Solidification, VII Vsesoyuznaya konferentsiya po rostu kristallov (VII All-Union Conf. on Crystal Growth), Moscow, 1988, vol. 3, pp. 245–247.

Schlichting, H., Boundary Layer Theory, New York: McGraw-Hill, 1968. Translated under the title Teoriya pogranichnogo sloya, Moscow: Nauka, 1974.

Maurakh, M.A. and Mitin, B.S., Zhidkie tugoplavkie okisly (Liquid Refractory Oxides), Moscow: Metallurgiya, 1979.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Gurov, V.V., Kirdyashkin, A.G. Sectorial Structure of Chrysoberyl Crystals Grown by Horizontal Directional Solidification. Inorganic Materials 37, 44–46 (2001). https://doi.org/10.1023/A:1026733310295

Issue Date:

DOI: https://doi.org/10.1023/A:1026733310295