Abstract

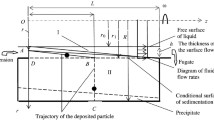

Centrifugal separation of low-concentration suspension in a biconical rotor of a centrifuge was modeled numerically. A system of equations describing the motion of solid particles in a fluid flow was constructed and solved. The effect of geometric parameters of the centrifuge rotor on the separation efficiency was demonstrated.

Similar content being viewed by others

References

Sokolov, V.I., Tsentrifugirovanie (Centrifugation), Moscow: Khimiya, 1976.

Shkoropad, D.E. and Novikov, O.P., Tsentrifugi i separatory dlya khimicheskikh proizvodstv (Centrifuges and Separators for Chemical Industries), Moscow: Khimiya, 1987.

Volkov, Yu.P. and Svetlov, S.A., Zh. Prikl. Khim., 2001, vol. 74, no. 11, pp. 1812-1814.

Gosman, A.D., Pun, W.M., Runchal, A.K., et al., Heat and Mass Transfer in Recirculating Flows, London: Academic, 1969.

Fortier, A., Mecanique des suspensions, Paris: Masson, 1967.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Pavlova, N.V., Spiridonov, F.F., Svetlov, S.A. et al. Effect of Design Parameters of the Centrifuge Rotor on Separation of Supensions. Russian Journal of Applied Chemistry 76, 1094–1098 (2003). https://doi.org/10.1023/A:1026358311879

Issue Date:

DOI: https://doi.org/10.1023/A:1026358311879