Abstract

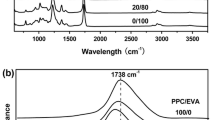

One Polycaprolactam (PCPL) polymer and three cationic dyeable poly(ethylene terephthalate) (CD-PET) polymers were blended mechanically in the proportions of 90/10, 80/20, 70/30, 60/40, 50/50, 40/60, 30/70, 20/80, 10/90 in a melt twin-screw extruder to prepare twenty-seven PCPL/CD-PET polyblended polymers. The molar ratios of 5-sodium sulfonate dimethyl isophthalate (5-SSDMI) for three CD-PET polymers were 2, 6 and 10%, respectively. This study investigated the thermal and mechanical properties of PCPL/CD-PET polyblended materials using gel permeation chromatograph (GPC), nuclear magnetic resonance (NMR), gas chromatography (GC), potentiometer, thermogravimetric analysis (TGA), differential scanning calorimetry (DSC), scanning electron microscope (SEM), extension stress-strain measurement, density gradient method and rheometer. Experimental results of the thermal properties indicated PCPL and CD-PET molecules easily formed individual domains. PCPL and CD-PET polymers were proved to be immiscible system even when CD-PET possessed higher 5-SSDMI content. Rheological behaviour of PCPL/CD-PET polyblends exhibited negative-deviation blends (NDB). The measurements of densities showed linear variation with the blend ratio of PCPL/CD-PET polyblends. The SEM pictures displayed the blend ratio of PCPL/CD-PET was 50/50, the morphological aggregation of a larger size from 3 to 5 μm in diameter was observed. Experimental results of the mechanical properties indicated the 50/50 blend of PCPL/CD-PET showed a minimum tensile strength.

Similar content being viewed by others

References

G. V. Vinogradov, B. V. Yarlykov, M. V. Tsebrenko, A. V. Yudin and T. I. Ablazova, Polymer, 16, 609 (1975).

T. I. Ablazova, M. V. Tsebrenko, A. V. Yudin, G. V. Vinogradov, B. V. Yarlykov, J. Appl. Polym. Sci., 19, 1781 (1975).

J. L. White, A. P. Plochoki and H. Tanaka, Polym. Engng. Rev., 1, 217 (1981).

J. W. Barlow and D. R. Paul, Polym. Engng. Sci., 21(15), 985 (1981).

K. Dimov, M. Savov and J. Georgiev, Ang. Makromol. Chem., 84, 119 (1980).

K. Dimov and M. Savov, Vysokomol. Soed., A22, 65 (1980).

M. Evstative and S. Fakirov, Polym. Networks Blends, 4(1), 25 (1994).

G. Serpe, J. Jarrin and F. Dawans, Polym. Engng. Sci., 30(9), 553 (1990).

F. Li, Y. Chen, W. Zhu, X. Zhang and M. Xu, Polym., 39(26), 6929 (1998).

J.M. Willis and B. D. Favis, Polym. Engng. Sci., 28(21), 1416 (1988).

J.M. Willis, V. Caldas and B. D. Favis, J. Mater. Sci., 26, 4742 (1991).

H. Zhang, S. Li and H. Luo, J. Appl. Polym. Sci., 34, 1353 (1987).

Y. Wang, Z. Chui, G. Qian and Z. Wu, J. China Textile University, 1, 39 (1988).

G. Li, L. Gu and T. Sun, J. China Textile University, 10(2), 34 (1993).

S. K. Pal, R. S. Gandhi and V. K. Kothari, J. Appl. Polym. Sci., 61, 401 (1996).

L. A. Utracki, Polym. Engng. Sci., 23(11), 602 (1983).

C. D. Han and Y. W. Kim, J. Appli. Polym. Sci., 19, 2831 (1975).

M. Kasajima, Bull. Coll. Eng. Hosei Univ., 15, 1 (1979).

C. K. Shin, Polym. Engng. Sci., 16, 742 (1976).

D. D. Patterson, Polym. Engng. Sci., 22, 64 (1982).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Hsiao, K., Shu, YC. & Tsen, WC. Thermal and Mechanical Properties of Polyblends of Polycaprolactam with Cationic Dyeable Poly(ethylene terephthalate). Journal of Polymer Research 10, 161–169 (2003). https://doi.org/10.1023/A:1026056214160

Issue Date:

DOI: https://doi.org/10.1023/A:1026056214160