Abstract

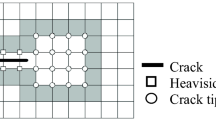

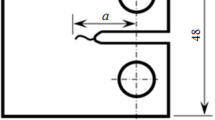

A computational approach to the optimization of service properties of two-phase materials (in this case, fracture resistance of tool steels) by varying their microstructure is developed. The main points of the optimization of steels are as follows: (1) numerical simulation of crack initiation and growth in real microstructures of materials with the use of the multiphase finite elements (MPFE) and the element elimination technique (EET), (2) simulation of crack growth in idealized quasi-real microstructures (net-like, band-like and random distributions of the primary carbides in the steels) and (3) the comparison of fracture resistances of different microstructures and (4) the development of recommendations to the improvement of the fracture toughness of steels. The fracture toughness and the fractal dimension of a fracture surface are determined numerically for each microstructure. It is shown that the fracture resistance of the steels with finer microstructures is sufficiently higher than that for coarse microstructures. Three main mechanisms of increasing fracture toughness of steels by varying the carbide distribution are identified: crack deflection by carbide layers perpendicular to the initial crack direction, crack growth along the network of carbides and crack branching caused by damage initiation at random sites.

Similar content being viewed by others

References

Barker, L.M. (1981). Short rod and short bar fracture toughness specimen geometries and test methods for metallic materials. Fracture Mechanics ASTM STP 743, 456–475.

Berns, H., Broeckmann, C. and Weichert, D. (1997). Fracture of hot formed ledeburitic chromium steels. Engineering Fracture Mechanics 58(4), 311–325.

Broberg, K.B. (1997). The Cell Model of Materials. Computational Mechanics 19(7), 447–452.

Broeckmann, C. (1994). Bruch karbidreicher Stähle - Experiment und FEM-Simulation unter Berücksichtigung des Gefüges. Dissertation, Ruhr-Universität Bochum.

Chelidze, T. and Gueguen, Y. (1990). Evidence of fractal fracture. Int. J. Rock Mech. Min. Sci. 27(3), 223–225.

Gross-Weege, A., Weichert, D. and Broeckmann, C. (1996). Finite element simulation of crack initiation in hard two-phase materials. Comp. Mat. Sci. 5, 126–142.

Iturriza, I. and Rodriguez Ibabe, J.M. (2000). 5th Interim technical reports on the project ‘Influence of Micromechanical Mechanisms of Strength and Deformation of Tool Steels under Static and Cyclic Load’, Creusot Loire, France.

Jirasek, M. (1998). Finite elements with embedded cracks, LSC Report, Lausanne, EPFL.

LARSTRAN, LASSO Ingenieurgesellschaft, Leinfelden-Echterdingen, Germany.

Lehmann A. (1995). Modellierung des Bruchverhaltens von Schnellarbeitsstählen unter Beachtung bauteilspezifischer Einflüsse, Diplomarbeit, TU Bergakademie Freiberg.

Lippmann, N. (1995). Beitrag zur Untersuchung des Bruchverhaltens von Werkzeugen aus Schnellarbeitsstählen unter statischer Beanspruchung, Dissertation, Freiberg.

Lippmann, N., Lehmann, A., Steinkopff, Th. and Spies, H.-J. (1996). Modelling the fracture behaviour of high speed steels under static loading. Comp. Mat. Sci. 7, 123–130.

Mishnaevsky, L., Jr. (1997). Damage and Fracture of Heterogeneous Materials, Balkema, 230 pp.

Mishnaevsky, L. Jr. (1996). Determination for the time to fracture of solids. Int. J. Fracture 79(), 341–350.

Mishnaevsky, L. Jr. and Schmauder, S. (2001). Continuum mesomechanical finite element modeling in materials development: a state-of-the-art review. Applied Mechanics Reviews, 54, 1.

Mishnaevsky, L. Jr. and Schmauder, S. (1999). Pursuance and Analysis of SEM-in-situ- Experiments on the Deformation and Fracture of Cold Work and High Speed Steels, Report for Boehler Edelstahl GmbH, MPA, 35 pp.

Mishnaevsky, L. Jr. and Schmauder, S. Optimization of Fracture Resistance of Ledeburitic Tool Steels: a Fractal Approach, ‘Steels and Materials for Power Plants’, (Edited by P. Neumann et al.), Proceedings of EUROMAT-99 (European Congress on Advanced Materials and Processes, Munich, 1999), Vol. 7, Wiley-VCH Verlag, Weinheim.

Mishnaevsky, L. Jr. and Shioya, T. (2001). Optimization of materials microstructures: Information theory approach. Journal of the School of Engineering, The University of Tokyo, 48, 1–13.

Mishnaevsky Jr, L., Dong, M., Hoenle, S. and Schmauder, S. (1999). Computational mesomechanics of particlereinforced composites. Comp. Mater. Sci. 16(1–4), 133–143.

Mishnaevsky, L. Jr., Lippmann, N. and Schmauder, S. (2001). Experimental-Numerical Analysis of Mechanisms of Damage Initiation in Tool Steels, Proc. 10th International Conference Fracture, 3–7 Dec 2001, Honolulu, USA, CD ROM.

Mishnaevsky, L. Jr., Mintchev, O. and Schmauder, S. (1998). FE-simulation of crack growth using a damage parameter and the cohesive zone concept, In ECF 12 - Fracture from defects, Proc. 12th European Conference on Fracture (Sheffield, 1998). (Edited by M. W. Brown, E. R. de los Rios and K. J. Miller), London, EMAS, 2, 1053–1059.

Mishnaevsky, L. Jr. and Schmauder, S. 2nd-4th Interim technical reports on the project ‘Influence of Micromechanical Mechanisms of Strength and Deformation of Tool Steels under Static and Cyclic Load’, 1998-1999, Creusot Loire, France.

Rashid, Y.R. (1968) Ultimate strength analysis of prestressed concrete pressure vessels. Nucl. Engng. And Design 7, 334–344.

Siegmund, T., Bernauer, G. and Brocks, W. (1998). Two models of ductile fracture in contest: porous metal pasticity and cohesive elements, ‘ECF 12 - Fracture from Defects’, Proc. 12th European Conference on Fracture (Sheffield, 1998). (Edited by M.W. Brown, E.R. de los Rios and K. J. Miller). EMAS, 2, 981–985.

Tetelman, A.S. and McEvily, A.J., Jr. (1967). Fracture of Structural Materials. New York: Wiley.

Trubitz, P. Messung der elastischen Eigenschaften von Karbiden und der Matrix von Stahl X155CrVMo12-1, Prüfbericht, 26.11.1998, TU BA Freiberg.

Tvergaard, V. and Hutchinson, J.W. (1988). Effect of T-stress on mode I crack growth resistance in a ductile solid. Int. J. Solids Struct. 31(6), 823–833.

van Vroonhoven, J. (1996). Dynamic crack propagation in brittle materials: Analyses based on fracture and damage mechanics, Eindhoven, Philipps Electronics, 195 pp.

Weihe, S., Kröplin, B. and de Borst, R. (1998). Classification of smeared crack models based on material and structural properties. Int. J. Solids and Structures 35(12), 1289–1308.

Weihe, S. and Kröplin, B. (1995). Fictitiuos crack models: A classification approach. Proc. FRAMCOS II (2nd Int. Conf. Fracture Mechanics of Concrete and Concrete Structures), (Editeb by F.H. Wittmann), Aedificatio Publ., 2, 825–840.

Wulf, J. (1995). Neue finite-elemente-methode zur simulation des duktilbruchs in Al/SiC. dissertation. MPI für Metallforschung, Stuttgart.

Xia, L. and Shih, C.F. (1995). Ductile crack growth - II. Void nucleation and geometry effects on macroscopic fracture behavior. J. Mech. Phys. Solids 43(11), 1953–1981.

Xia, L., Shih, C.F. and Hutchinson, J.W. (1995). A computational approach to ductile crack growth under large scale yielding conditions. J. Mech. Phys. Solids 43(3), 389–413.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Mishnaevsky, L., Lippmann, N. & Schmauder, S. Computational modeling of crack propagation in real microstructures of steels and virtual testing of artificially designed materials. International Journal of Fracture 120, 581–600 (2003). https://doi.org/10.1023/A:1025524214322

Published:

Issue Date:

DOI: https://doi.org/10.1023/A:1025524214322