Abstract

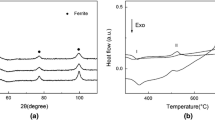

The iron-silicon-aluminum alloys (particularly Sendust) have been widely used in applications requiring high saturation flux density, low coercive force and high electrical resistivity. For this reason they have been promising for magnetic thin film heads, however, they are too hard and brittle to be made into thin films by rolling, or into three-dimensional products of complex shape by mechanical working or a conventional powder metallurgy process. The reduction in the size and weight of devices that can be accomplished through the use of Sendust has had an important effect on technical development. In this report, magnetic characteristics of Sendust ring samples produced by the powder metallurgy process with spray drying were investigated. After gas-atomized Sendust powders were mixed with paraffin compounds, these powders were granulated by the spray drying method using organic binder consisting of polyvinyl alcohol (PVA) and plasticizer in the range from 0.1 to 0.5 wt% of PVA, in order to improve the powder flowability and mechanical strength of compacted bodies. Results show that the present method is an excellent process for producing near-net-shaped parts with high performance and high dimensional precision after sintering.

Similar content being viewed by others

References

H. Masumoto and T. Yamamoto, J.Jpn.Inst.Metals 1 (1937) 127.

T. Miyazaki, T. Tsuzuki, T. Kosakai and Y. Fujimoto, ibid. 46 (1982) 1111.

S. Hanada, S. Watanabe, T. Sato, S. Ono and O. Izumi, ibid. 47 (1983) 336.

M. Takahashi, T. Miyazaki and T. Watanabe, in Proceeding of the 100th Spring Meeting of Jpn. Inst. Metals, March 1977, p. 174.

T. Yamamoto and Y. Utsushikawa, J.Jpn.Inst.Metals 40 (1976) 975.

H. H. Helms, Jr. and E. Adams, J.Appl.Phys. 35 (1964) 871.

T. Kawaguchi, R. Tamuraand H. Yamamoto, J.Jpn.Soc.Powder Powder Metall. 14 (1967) 20.

T. Kawaguchi, H. Yamamoto, T. Nakamura and M. Ishiyama, ibid. 15 (1968) 5.

H. Yamamoto, ibid. 15 (1968) 288.

K. Master, in “Spray Drying Handbook” (Harlow, Longman Scientific & Technical, 1991).

Y. Kishimoto and O. Yamashita, J.Jpn.Soc.Powder Powder Metall. 43 (1996) 249.

O. Yamashita and Y. Kishimoto, Powder Metall. 41 (1998) 177.

Y. Kishimoto and O. Yamashita, J.Jpn.Soc.Powder Powder Metall. 44 (1997) 951.

Y. Kishimoto, M. Ueda and O. Yamashita, ibid. 43 (1996) 1449.

Y. Kishimoto and O. Yamashita, ibid. 44 (1997) 775.

M. Sagawa, S. Fujimura, N. Togawa, H. Yamamoto and Y. Matsuura, J.Appl.Phys. 55 (1984) 2083.

Richard M. Bozorth, in “Ferromagnetism” (D.Van Nostrand Company, Inc., 1968) p. 870.

A. S. Zaimovsky and I.P. Selissky, J.Phys. 4 (1941) 563.

T. Yamamoto, J.Inst.Elec.Comm.Engineers Jpn. 12 (1942) 277.

Idem., Trans.Inst.Elec.Engineers Jpn. 5 (1944) 175.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kishimoto, Y., Yamashita, O. & Makita, K. Magnetic properties of sintered sendust alloys using powders granulated by spray drying method. Journal of Materials Science 38, 3479–3484 (2003). https://doi.org/10.1023/A:1025157019440

Issue Date:

DOI: https://doi.org/10.1023/A:1025157019440