Abstract

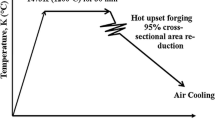

A low (0.2%) carbon steel has been subjected to heat treatment to form varying quantities of ferrite plus martensite in its microstructure. This was achieved by holding the samples in the two-phase (ferrite plus austenite) region at three different temperatures (750, 780, and 810 °C) for a specific duration followed by quenching in ice water. In another exercise, the steel was also subjected to annealing treatment by austenitizing at 890 °C followed by furnace cooling for comparison purposes. The samples were subjected to low-stress (three-body) abrasion tests using an ASTM rubber wheel abrasion test apparatus at different wheel speeds (150, 273 and 400 rpm corresponding to linear speeds of 1.79, 3.26 and 4.78 m/s respectively) for different sliding distances at a fixed load of 49 N. Crushed silica sand particles of size ranging from 212 to 300 μm were used as the abrasive medium. The wear rate of samples decreased progressively with sliding distance until a (nearly) steady-state condition was attained. This was considered to be due to abrasion-induced work hardening of subsurface regions as well as the greater tendency of protrusion of the harder martensite/pearlite phase at longer sliding distances, thereby providing greater resistance to wear. Decreasing wear rate with increasing treatment temperature 750–810 °C could be attributed to the greater volume fraction of the hard martensite phase in the samples containing ferrite plus martensite. The lower wear rate observed in the case of the samples containing ferrite plus martensite over the annealed ones comprising ferrite and pearlite was attributed to the higher bulk hardness of the former. Increasing linear speed from 1.79 to 3.26 m/s led to an increase in wear rate. This could be attributed to greater tendency of the abrasive particles to create deeper scratches and scouping (digging). A reduction in wear rate with a further increase in the linear speed from 3.26 to 4.78 m/s could be due to a change in the mechanism of wear from predominantly sliding to rolling of the abrasive particles in view of the increased plastic deformability characteristics of the specimens due to higher frictional heating. The present investigation clearly suggests that it is possible to attain a desired combination of bulk hardness and microstructure (consisting of ferrite plus martensite) leading to optimum abrasion resistance in low-carbon steels. The quantity of the two phases in turn could be varied by suitably controlling the heat-treatment temperature.

Similar content being viewed by others

Reference

K. Nakota, K. Araki and K. Kurihara, in: Formable HSLA and Dual-Phase Steels ed. A. T. Davenport (TMS-AIME, New York, 1979) p. 183.

R. G. Davies and C. L. Magee, in: Structure and Properties of Dual-Phase Steels, eds. R. A. Kott and J. W. Morries (TMS-AIME, New York, 1979) p. 1.

A. K. Jha, B. K. Prasad, O. P. Modi, S. Das and A. H. Yegnes-waran, Wear 254 (2003) 120.

M. Erdogan, J. Mater. Sci. 37 (2002) 3623.

B. K. Prasad and S. V. Prasad, Wear 151 (1991) 1.

J. Larsen-Badse and K. G. Mathew, Wear 14 (1969) 199.

J. Larsen-Badse, Trans. Metall. Soc. AIME 236 (1966) 1461.

M. A. Moore, Wear 28 (1974) 59.

M. M. Krushchov and M. A. Babichev, Frict. Wear Machine 19 (1965) 1.

P. L. Hurricks, Wear 26 (1973) 285.

S. Das, B. K. Prasad, A. K. Jha, O. P. Modi and A. H. Yegnes-waran, Wear 162–164 (1993) 802.

O. P. Modi, B. K. Prasad, A. K. Jha, S. Das, and A. H. Yegneswaran, Mater. Trans. JIM 35 (1994) 67.

R. Dasgupta, B. K. Prasad, O. P. Modi and A. K. Jha, J. Mater. Eng. Perf. 8 (1999) 437.

G. R. Speich, in: Fundamentals of Dual-Phase Steels The Metallurgical of Society, 1981) p. 1.

R. D. Lawson, B. L. Bramfitt, D. K. Matlock and G. Krauss, in: Fundamentals of Dual-Phase Steels, ed. R. A. Kott (AIME, New York, 1981) p. 347.

R. G. Davies, Met. Trans. A 9A (1978) 671.

R. G. Davies, Met. Trans A 9A (1978) 1549.

X. L. Cai, J. Feng and W. S. Owen, Met. Trans. A 11A (1980) 1683.

X. J. He, N. Terao and A. Berghezan, J. Mater. Sci., 18 (1984) 367.

Y. Tomota, Mater. Sci. Tech. 3 (1987) 415.

G. Krauss and A. R. Marder, Met. Trans. A 2A (1971) 2343.

G. S. Huppi, D. K. Matlock and G. Krauss, Scri. Metall. 14 (1980) 1239.

M. Erdogan and R. Priestner, Mater. Sci. Technol. 15 (1999) 1273.

M. Erdogan and R. Priestner, Mater. Sci. Technol. 18 (2002) 369.

Standard Practice for Conducting Dry Sand Rubber Wheel Abrasion Tests, ASTM Standard G 65–81 (Annual Book of ASTM Standards, Philadelphia, PA, 1981).

A. G. Gulyaev, ed., Physical Metallurgy, Vol. 1 (Mir Publishers, Moscow, 1978) p. 154.

I. Novikov, ed., Theory of Heat Treatment of Metals (Mir Publishers, Moscow, 1978) p. 208.

B. K. Prasad, S. V. Prasad and A. A. Das, Mater. Sci. Eng. A 156A (1992) 205.

B. K. Prasad, S. V. Prasad and A. A. Das, J. Mater. Sci. 27 (1992) 4489.

T. Jian-min, S. Ye-Ying, Z. Hua-Yi, Z. Ching-an and K. Xian-Wu, Tribol. Int. 18 (1985) 101.

L. Yingjie, B. Xingui and C. Keqiang, Tribol. Int. 18 (1985) 107.

B. K. Prasad, A. K. Patwardhan and A. H. Yegneswaran, J. Mater. Eng. Perf. 7 (1998) 130.

J. Larsen-Badse, Scri. Metall. 24 (1990) 821-826.

Metals Handbook, Vol. 8, Edition 9 (ASM, Ohio, USA), p. 240.

K. M. Mashloosh and T. S. Eyre, Tribol. Int. 18 (1985) 259.

M. A. Moore, Wear 17 (1951) 51.

O. Scheffler and C. Allen, Tribol. Int. 21 (1988) 127.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Modi, O., Prasad, B., Jha, A. et al. Low-Stress Abrasive Wear Behaviour of a 0.2% C Steel: Influence of Microstructure and Test Parameters. Tribology Letters 15, 249–255 (2003). https://doi.org/10.1023/A:1024865220280

Issue Date:

DOI: https://doi.org/10.1023/A:1024865220280