Abstract

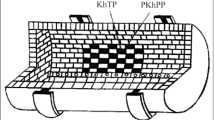

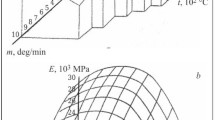

Results of a repair-and-maintenance program aimed at increasing the durability of the converter lining in an oxygen converter shop at the MISW JSC are reported. The program includes a single-round placement of the lining, the use of high-resistance PUPK-1-grade refractory components in high-wear zones, advanced methods for lining maintenance, development of high-resistance mixtures and taphole blocks, improvement of the converter process parameters, and introduction of advanced methods for lining wear monitoring.

Similar content being viewed by others

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Takhautdinov, R.S., Nosov, A.D., D'yachenko, V.F. et al. Using Periclase-Carbon Converter Linings at the Magnitogorskii Iron-And-Steel Works (MISW) Joint-Stock Co.. Refractories and Industrial Ceramics 44, 75–79 (2003). https://doi.org/10.1023/A:1024757508433

Issue Date:

DOI: https://doi.org/10.1023/A:1024757508433