Abstract

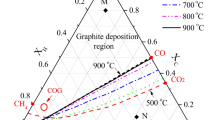

A theoretical analysis has been conducted into the thermodynamic role of iron and the dependence of possible metal-dusting occurrence on temperature, volumetric ratios of carburizing species CH4 and CO, and total pressure. The analysis indicates that the equilibrium carbon activity with cementite (a C(Fe 3 C/Fe )) decreases with increasing temperature, and becomes lower than unity in excess of approximately 1000°C. This critical temperature could be the upper-temperature limit for decomposition of cementite in metal dusting. The temperature regime for possible metal dusting in either CH4–H2 or CO–CO2 gas mixtures increases with increasing volumetric ratio of CH4 or CO. Increasing total pressure leads to a reduction of this temperature regime in CH4–H2 but an expansion in CO–CO2. Comparatively, this temperature regime in CO–CO2 is shifted more towards lower temperatures, and iron is likely more susceptible to metal-dusting attack in CO–CO2 due to the higher reverse carbon-activity gradient established.

Similar content being viewed by others

REFERENCES

R. F. Hochman, Proceedings of the 4th International Congress on Metal Corrosion (ed. N. E. Hammer), NACE, Houston, 258(1972).

F. Dettenwanger, D. Grotmann, H. Friedrich, E. Berghof-Hasselbächer, M. Schorr, and M. Schütze, Mater. and Corros. 50, 289(1999).

M. L. Holland and H. J. De Bruyn, Intern. J. Pressure Vessel and Piping 66, 125(1996).

K. L. Baumert and J. J. Hoffman, Mater. Perform. 37, 60(1998).

H. J. Grabke, Carburization— A High Temperature Corrosion Phenomenon, Chapter one, Part I, Materials Technology Institute, 1998.

R. Schneider, E. Pippel, J. Woltersdorf, S. Strauss, and H. Jürgen Grabke, Steel Res. 68, 326(1997).

S. Strauβ, R. Krajak, and H. J. Grabke, Mater. Corros. 50 (11), 622(1999).

C. M. Chun, J. D. Mumford, and T. A. Ramanarayanan, J. Electrochem. Soc. 147, 3680(2000).

C. M. Chun, J. D. Mumford, and T. A. Ramanarayanan, J. Electrochem. Soc. 149, B348-B355 (2002).

H. J. Grabke, R. Krajak, and J. C. Nava Paz, Corros. Sci. 35, 1141-1150 (1993).

E. Pippel, J. Woltersdorf, H. J. Grabke, and S. Strauss, Steel Res. 66, 217(1995).

E. Pippel, J. Woltersdorf, and R. Schneider, Mater. Corros. 49, 309(1998).

Q. Wei, E. Pippel, J. Woltersdorf, and H. J. Grabke, Mater. Corros. 50, 628(1999).

S. R. Shatynski, Oxid. Met. 13, 105(1979).

JANAF Thermodynamic Data, Dow Chemical Co., Midland, Mich., 1960–1961.

R. Yin, Carburization behavior of iron-based alloys in methane-hydrogen gas mixtures, Ph.D. Dissertation, King Fahd University of Petroleum and Minerals, Saudi Arabia, May 2002.

J. C. Nava Paz, and H. J. Grabke, Oxid. Me. 39, 437(1993).

S. R. Shatynski, and H. J. Grabke, Arch. Eisenhuettenwes. 49, 129(1978).

H. J. Grabke, and E. M. Müller-Lorenz, Mater. Corros. 49, 317(1998).

H. J. Grabke, E. M. Müller-Lorenz, B. Eltester, and M. Lucas, Mater. at High Temp. 17, 339(2000).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Yin, R. Thermodynamic Aspects of Iron in Metal Dusting. Oxidation of Metals 60, 103–116 (2003). https://doi.org/10.1023/A:1024669430565

Issue Date:

DOI: https://doi.org/10.1023/A:1024669430565