Abstract

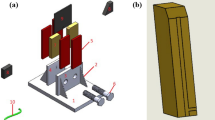

We demonstrate the changes in the microstructure of the surface layers of D16 alloy cladded with aluminum in the course of laser treatment. The process of melting can start for relatively low intensities of laser beams on the interface of the alloy and clad layer with subsequent propagation of the front of melting both into the bulk of the alloy and to the surface. As the intensity of laser irradiation increases, the process of melting starts from the surface and the thickness of the remelted and recrystallized layer increases. Laser heating removes textures and decreases the microhardness of the surface layers of the alloy.

Similar content being viewed by others

REFERENCES

V. S. Kovalenko, Laser Hardening of Machine Parts [in Russian], Naukova Dumka, Kiev (1987).

A. G. Grigoryants and A. N. Safonov, Methods for Surface Laser Treatment [in Russian], Vysshaya Shkola, Moscow (1987).

B. Dubrujeaud, A. Fontes, P. Forged, et. al., “Surface modification using high-power lasers: influence of surface characteristics on properties of laser processed materials,” Surface Eng., 13, No. 6, 461–470 (1997).

A. Bransden, “Laser surface treatment,” in: Proc. of the Internat. Symp. for Electromachining, Aachen, D (May, 1998), V. 1376 (1998), pp. 129–141.

F. Klocke, K. Sweeney, A. Demmer, and C. Wagner, “Laser applications in sheet metal part production,” in: Proc. of the 6th Internat. Conf. “Sheet Metal-1998” (April, 1998), Vol. 1, the Netherlands (1998), pp. 81–91.

K. G. Watkins, M. A. McMahon, and W. M. Steen, “Microstructure and corrosion properties of laser surface processed aluminum alloys: a review,” Mat. Sci. Eng., Part A (Structural Materials: Properties, Microstructure, and Processing), A231, No. 1–2, 55–61 (1997).

H. Pokhmurs'ka, L. Kviatkovski, and W. Kalita, “Corrosion behavior of laser remelted aluminum alloy,” Fiz.-Khim. Mekh. Mater. (Special Issue), 2, No. 3, 559–564 (2002).

H. Pokhmurs'ka, N. Chervins'ka, and R. Krupa, “Electrochemical characteristics of electric-arc coatings on aluminum alloy,” Fiz.-Khim. Mekh. Mater. (Special Issue), 2, No. 3, 573–576 (2002).

T. T. Wong and G. Y. Liang, “Effect of laser melting treatment on the structure and corrosion behavior of aluminum and Al-Si alloys,” in: Proc. of the Third Asia Pacific Conf. on Materials Processing (Hong Kong, November 1996), J. Mater. Proc. Technol., 63, No. 1–3, 930–934 (1997).

Cui Hongwei, Geng Haoran, Tian Xianfa, et. al., “Laser surface remelting and resolidifying process of Zn-27 wt.% Al alloy,” Mat. Sci. Eng., Part A, 323, Nos. 1–2, 103–109 (2002).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Pokhmurs'ka, H.V. Structural Changes in the Surface Layer of D16 Alloy Cladded with Aluminum in the Process of Laser Heating. Materials Science 38, 889–893 (2002). https://doi.org/10.1023/A:1024228305396

Issue Date:

DOI: https://doi.org/10.1023/A:1024228305396