Abstract

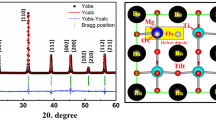

This paper is concerned with the feasibility and reproducibility of the ultrarapid quenching process used to fabricate Bi2−x Sb x Te and Bi2−x Sb x Te2 alloys for thermoelectric applications. Microstructural properties of the materials, obtained in the shape of foils, were studied concerning the phase analysis, cell parameters, texture, and microstructure observations. The Bi2−x Sb x Te alloys were found to have the (2 0 \(\bar 2\) 3) texture. The (2 0 \(\bar 2\) 4) texture, with an additional (1 1 \(\bar 2\) 0) component for x values greater than 0.4, was predominant for Bi2−x Sb x Te2 foils. The electrical properties of these materials were then characterized by measuring the Seebeck coefficient, Hall coefficient, and electrical resistivity. It was found that Bi2−x Sb x Te foils changed from n- to p-type for an x-value of about 1.2. A maximum Seebeck coefficient, |α|, of 36×10−6 V K−1 was measured for Bi2Te. In the case of Bi2−x Sb x Te2 foils, the change from n- to p-type was observed for an x value of about 1. A maximum Seebeck coefficient, |α|, of 32×10−6 V K−1, was measured for Bi1.4Sb0.6Te2. Measurements of the temperature-dependent electrical resistivity, Hall and Seebeck coefficients of the foils were carried out and the analysis revealed a semi-metallic behavior.

Similar content being viewed by others

References

A. Sher, M. Shiloh, D. Ilzycerl and D. Eger, J. Electron. Mater. 12 (1983) 247.

H. J. Goldsmid, in “Electronic Refrigeration”, edited by D. Rowe, Pion Limited, London (1987) p. 342.

M. M. Ibrahim, N. Afify, M. M. Hafiz and M. A. Mahmoud, J. Phys. Chem. Solids 51 (1990) 253.

M. J. Mcculley, G. W. Neudeck and G. L. Liedl, J. Vac. Sci. Technol. 10 (1973) 391.

I. S. Miroshnichenko, “Zakalka iz zhidkogo sostoyaniya (Liquid Quenching)” (Mettalurgiya Moscow, 1982) p. 166.

H. Herman, in “Treatise on Materials Science and Technology” (Academic Press, London, 1981) 441.

Y. Kim, S. Cho, A. Divenere, G. K. Wong, J. R. Meyer and J. B. Ketterson, Mater. Res. Soc. Symp. Proc. 545 (1999) 177.

K. Dovletov, N. K. Samokhotina, A. V. Anikin, A. Ashirov and K. Karayev, Izvestiya Akademii nauk turkmenskoi SSR. Seriya fiziko-tekhnicheskih i geologicheskih nauk 1 (1974) 119.

E. Zauyalov, V. Begigov and G. Nechelyustov, Dokl. Akad. Nauk SSSR 230 (1976) 1439.

E. L. Koukharenko, N. Frety, G. Nabias, V. G. Shepelevich and J. C. Tedenac, J. Crys. Growth 209 (2000) 773.

B. M. Goltsman, V. A. Kudinov and I. A. Smirnov, in “Semiconducting Thermoelectric Materials based on Bi2Te3” (Nauka, Moskow, 1972) p. 320.

M. Francombe, Philos. Mag. 10/108 (1964) 989.

E. L. Koukharenko, N. Frety, V. G. Shepelevich and J. C. Tedenac, J. Alloys Compd. 327 (2001) 1.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kukharenka, E., Fréty, N., Shepelevich, V.G. et al. Electrical and microstructural properties of Bi2−x Sb x Te and Bi2−x Sb x Te2 foils obtained by the ultrarapid quenching process. Journal of Materials Science: Materials in Electronics 14, 383–388 (2003). https://doi.org/10.1023/A:1023956819190

Issue Date:

DOI: https://doi.org/10.1023/A:1023956819190