Abstract

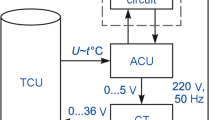

Maintenance of temperature-rate modes of deformation is considered for isothermal superplastic stamping on a thermocompression unit. In the automated control system proposed for a thermocompression unit a PC regulates the heating rate of the working elements by using custom software and method for obtaining the initial information.

Similar content being viewed by others

REFERENCES

S. Z. Figlin, Isothermal Deformation of Metals [in Russian], Mashinostroenie, Moscow (1978).

Isothermal Stamping of Aluminum and Magnesium Alloys. Technical Handbook [in Russian], Izd. INAT, Moscow (1996).

V. I. Galkin, Compaction Laws and Technology of Production of Hollow Products from Fibrous Metal–Matrix Composites [in Russian], Izd. MATI (Moscow Aviation Technology Institute), Moscow (1987).

A. N. Parshikov, Study and Development of a Production Technology for Ribbed Aluminum Alloy Panels [in Russian], Izd. MATI (Moscow Aviation Technology Institute), Moscow (2000).

Rights and permissions

About this article

Cite this article

Bazhenov, M.G., Galkin, V.I., Zharov, M.V. et al. Automated Control System for Thermocompression Unit. Measurement Techniques 46, 56–58 (2003). https://doi.org/10.1023/A:1023465623044

Issue Date:

DOI: https://doi.org/10.1023/A:1023465623044