Abstract

After rolling of aluminium alloys, static recrystallisation can modify product properties. The variation of properties throughout the stock thickness is of special interest to the producer. Predicting the recrystallisation kinetics by the combination of finite element method (FEM) with the various metallurgical models has attracted tremendous interest in both academia and industry. However, controversial results on the through-thickness distribution of the recrystallisation kinematics have been reported. The present paper attempts to explain this phenomenon from the viewpoint of the recrystallisation mechanism: the total stored energy, the growth rate of recrystallised grains, the Zener Hollomon parameter and the distribution of the equivalent strain. To improve the prediction accuracy, some new approaches are proposed on the calculation of equivalent strain and the Zener-Hollomon parameter. Some aspects related to the experimental establishment of these models are also critiqued.

Similar content being viewed by others

References

E. Nes, Progress in Materials Science 41 (1998) 129.

C. M. Sellars and Q. Zhu. Materials Science and Engineering A 280(1) (2000) 1.

M. Goerdeler and G. Gottstein, Materials Science & Engineering A 309/310 (2001) 377.

G. Gottstein, V. Marx and R. Sebald, J. Shanghai Jiaotong University E-5(1) (2000) 49.

G. Gottstein, V. Marx and R. Sebald, in “The Fourth Inter. Conf. On Recrystallisation and Related Phenomenoa” edited by T. Sakai and H. G. Suzuki (Japan, 1999) p. 15.

H. R. Shercliff and A. M. Lovatt, Phil. Tran. R. Soc. Lond. A 357 (1999) 1621.

W. A. Johnson and R. F. Mehl, Trans. AIME 135 (1939) 416.

M. Avrami, J. Chem. Phys. 7 (1939) 1103.

A. N. Kolmogorov, USSR Ser. Metemat. 1 (1937) 355.

R. A. Vandermeer and D. Juul jensen, Metallurgical and Materials Transactions A 26A, 9 (1995) 2227.

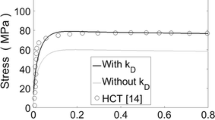

B. K. Chen, P. F. Thomon and S. K. Choi, Materials Science and Technology 8 (1992) 72.

A. McLaren and C. M. Sellars, in “Strip Casting, Hot and Cold Working of Stainless Steels” edited by Ryan N. D. et al. (Met. Soc. CIM, Montreal, Canada, 1993) p. 107.

T. A. Dauda and A. J. McLaren, in “Modelling of Metal Rolling Processes 3,” edited by J. H. Beynon et al. (London, 1999) p. 257.

H. L. Yiu et al., in “Hot Deformation of Aluminum Alloys,” edited by T. G. Langdon et al. (Detroit, 1999) p. 509.

E. Nes and K. Marthinsen, Proc. in “Hot Deformation of Aluminium Alloys II,” edited by T. R. Bieler et al. (TMS, Chicago, 1998) p. 171.

H. E. Vatne, T. Furu, R. Ørsund and E. Nes, Acta Mater. 44(1) (1996) 4463.

H. E. Vatne, F. Perocheau, H. E. Ekstr m, L. Poizat, K. V. Nord, M. Knut, E. Lindh, J. Hagstr m and T. Furu, Mater. Sci. Forum 331-337 (2000) 551.

A. J. Brand, S. Kalz and R. Kopp, Comput. Mater. Sci. 7 (1996) 242.

M. S. Mirza, C. M. Sellars, K. Karhausen and P. Evans, Materials Science and Technology 17 (2001) 874.

M. A. Wells, D. J. Lloyd, I. V. Samarasekera, J. K. Brimacombe and E. B. Hawbolt, Metallurgical and Materials Transactions B 29B (1998) 709.

M. P. Black, R. L. Higginson and C. M. Sellars, Materials Science and Technology 17 (2001) 1055.

A. J. McLaren. PhD thesis, University of Sheffield, 1994.

X. Duan and T. Sheppard, Journal of Materials Processing Technology 125/126 (2002) 181.

X. Duan and T. Sheppard, Computational Materials Science, in press.

Y. Huang and F. J. Humphreys, Acta Mater. 48 (2000) 2017.

Y. Huang and F. J. Humphreys, Acta Mater 48 (1999) 2259.

D. J. Jensen, M. T. Lyttle and N. Hansen, in “Hot Deformation of Aluminium Alloys II,” edited by T. R. Bieler et al. (TMS, Chicago, 1998) p. 9.

M. A. Zaidi and T. Sheppard, Metal Sciences 16 (1982) 229.

N. Raghunathan and T. Sheppard, Materials Science and Technology 5 (1989) 542.

I. Gutierrez et al., Materials Science and Engineering A 102 (1988) 77.

G. Liserre et al., in “Sixth International Conference on Aluminium Alloys,” edited by T. Sao et al. (Toyohashi, Japan, July 1998) p. 395.

T. Sheppard et al., in “Microstructural Control in Aluminium Alloys: Deformation, Recovery and Recrystallization,” New York, 27 Feb. 1985, edited by Chia, E. Henry and H. J. McQueen (The Metallurgical Society, Inc., New York, 1986) p. 19.

C. M. Sellars et al., in “Microstructural Control in Aluminium Alloys: Deformation, Recovery and Recrystallization.” New York, 27 Feb. 1985, edited by C. E. Henry and H. J. McQueen (The Metallurgical Society, Inc., New York, 1986) p. 179.

P. L. Orsetti Rossi and C. M. Sellars, Materials Science Forum.217-222 (1996) 379.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Sheppard, T., Duan, X. Modelling of static recrystallisation by the combination of empirical models with the finite element method. Journal of Materials Science 38, 1747–1754 (2003). https://doi.org/10.1023/A:1023283911730

Issue Date:

DOI: https://doi.org/10.1023/A:1023283911730