Abstract

The electrical discharge machining process is an effective way to machine hard alloys. A homogenized dual phase Fe-24.0%Mn-8.3%Al-5.0%Cr-0.38%Si-0.34%Mo-0.45%C (wt%) alloy casting piece was employed to study the phase transformation and microstructure phenomena of recast layers by means of electrical discharge machining. The wave-like recast layers appear with micro cracks. The thickness of the recast layer increases with pulse duration. When the pulse duration ranges from 200 to 300 μs, the discharge current has no influence on the thickness of the recast layer. The copper concentration is high in the recast layer caused by the melting of the copper electrode. The copper contents of the recast layer increase with the pulse duration and the discharge current.

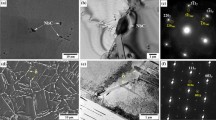

The novel solidification microstructures of the recast layer can be classified as (1) a dense and fine dendritic outermost sublayer, (2) a coarse dendritic intermediate sublayer and (3) an innermost γ recast zone. The average chemical composition of the recast sublayers is Fe-19.007%Mn-8.377%Al-2.981%C-4.505%Cr-0.627%Cu-0.377%Mo-0.376%Si (wt%). The novel structure of the recast sublayer is identified as (Fe,Mn)3AlCx, which was formed due to the re-melting of the matrix and the carburization of the cracked dielectric fluid. The precise lattice parameter, a o, of the (Fe,Mn)3AlC x phase measured by extrapolation against cos2θ/sinθ is 0.3801 nm. The microhardness of the recast layers is as high as Hmv574 due to the existence of (Fe,Mn)3AlCx carbide.

Similar content being viewed by others

References

L. C. Lim, L. C. Lee, Y. S. Wong and H. H. Lu, Mater. Sci. Technol 3(7) (1991) 239.

L. C. Lee, L. C. Lim, V. Narayanan and V. C. Venkatesh, Int. J. Mach. Tool Manufact. 28(4) (1988) 359.

R. A. Hadfield, PUS Patent 422403 (1887).

J. R. Mitchell and M. E. Potter, US Patent 3201230 (1965).

J. W. Lee, J. G. Duh and S. Y. Tsai, Surf. Coat. Technol. 153(1) (2002) 59.

J. G. Duh, J. W. Lee and C. J. Wang, J. Mater. Sci. 23 (1988) 2649.

J. G. Duh and J. W. Lee, J. Electrochem. Soc. 136(3) (1989) 847.

B. K. Zuidema, D. K. Subramanyam and W. C. Leslie, Metall. Trans. A 18 (1987) 1629.

J. W. Lee, in Proceedings of 16th National Conference on Mechanical Engineering (The Chinese Society of Mechanical Engineering, Taiwan, Dec. 1999) Vol. 4, p.158.

C. H. Kahng and K. P. Rajurkar, CIRP Ann. 25(1) (1977) 77.

A. G. Mamlis, G. C. Vosniakos, N. M. Vaxevandis and J. Prohszka, J. Mech. Working Technol. 15(1) (1988) 335.

K. P. Rajurkar and S. M. Pandit, J. Eng. Ind. (Trans. ASME) 106(2) (1984) 171.

L. Massarelli and M. Marchionni, Met. Technol. 4(2) (1977) 100.

J. S. Soni, Wear 177(2) (1994) 71.

J. P. Kruth, L. Stevens, L. Froyen and B. Lauwers, CIRP Ann. 44(1) (1995) 169.

C. P. Tabrett, J. Mater. Sci. Let. 15(20) (1996) 1792.

H. K. Lloyd and R. H. Warren, J. Iron Steel Inst. 203(3) (1965) 238.

J. S. Soni and G. Chakraverti, J. Mater. Proc. Technol. 56(1-4) (1996) 439.

Y. Fukuzawa, Yo Kojima, T. Tani, E. Sekiguti and N. Mohri, Mater. Manufact. Proc. 10(2) (1995) 195.

B. V. Sharov and IZV. AKAD. NAUK, SSSR Met. Topl. 3 (1959) 148.

G. F. Kosolapov and Yu. D. Tyapkin, Metalloved. Term. Obrab. Met. 41 (1955) 226.

M. A. E. R. Merdan and R. D. Arnell, Surf. Eng. 5(2) (1989) 96.

C. E. Hale and A. J. Baker, in “Alternate Alloying for Environmental Resistance,” edited by G. R. Smolik and Banerji (The Metallurgical Society of AIME, 1987) p. 67.

K. Sato, K. Tagawa and Y. Inoue, Metall. Trans. A 21 (1990) 6.

P. J. James, J. Iron Steel Inst. 207 (1969) 54.

G. L. Kayak, Met. Sci. Heat Treat. 11(2) (1969) 95.

K. H. Han and W. K. Choo, Metall. Trans. A 14 (1983) 973.

W. K. Choo and K. H. Han, ibid. 16 (1985) 5.

K. H. Han and W. K. Choo, ibid. 20 (1989) 205.

C. Y. Chao, C. N. Hwang and T. F. Liu, Scripta Metall. 34(1) (1996) 75.

J. W. Lee and T. F. Liu, Mater. Chem. Phys. 69 (2001) 192.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lee, JW. Microstructural evaluation and phase transformation of recast layers in electrical discharge machined dual phase Fe-Mn-Al alloy. Journal of Materials Science 38, 1679–1687 (2003). https://doi.org/10.1023/A:1023215424025

Issue Date:

DOI: https://doi.org/10.1023/A:1023215424025