Abstract

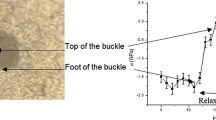

An Fe–25Cr alloy was oxidized in Ar at 973 K with or without external stresses of 30, 35, and 40MPa. A 0.1-μm thick Cr2O3 scale was formed during pretreatment, after which it grew obeying a parabolic rate law without formation of flaws, i.e., cracks and exfoliation. After the pretreatment, tensile stresses of 30, 35, and 40 MPa were applied to monitor cracking behavior of the oxide scale. Cracking commenced at the alloy grain boundaries by the end of a second-stage creep. In a third stage, cracks formed in the alloy grains, arrayed almost perpendicular to the direction of the tensile stress, with regular intercrack spacings. The average intercrack spacings (L) at grain boundaries are smaller than the intercrack spacing of the grains, and the spacings are given by the power law relation: L∝(ε⋅)n, with strain rate exponents n of -0.22 for grains and −0.44 for grain boundaries. It appears that the local strain rate at grain boundaries is much larger than that of the grain as well as that the toughness of the oxide formed on the grain boundaries may be less than that of the grains. Indentation with a Vickers micro hardness tester indicated that the adhesion and fracture toughness of the oxide scale decreased both with growth of the oxide scale and creep deformation of the alloy substrate.

Similar content being viewed by others

REFERENCES

J. Robertson and M. I. Manning, Mater. Sci. Technol. 6, 81–91 (1990).

A. Atkinson and R. Guppy, Mater. Sci. Technol. 7, 1031–1041 (1991).

M. M. Nagl and W. T. Evans, J. Mater. Sci. 28, 6247–6260 (1993).

J. R. Nicholls, H. E. Evans, and S. R. J. Saunders, Mater. High Temp. 14, 5–13 (1997).

P. Hancock and J. R. Nicholls, Mater. High Temp. 12, 209–218 (1994).

M. Schütze, in Protectiûe Oxide Scales and Their Breakdown, D. R. Holmes, ed., translated by R. B. Waterhouse (Wiley, New York, 1997).

H. Riedel, Met. Sci. 16, 569–574 (1982).

M. Schütze, Oxid. Met. 24, 199–232 (1985).

L. Berchtold, M. Welker, and H. G. Sockel, Werksto. Korros. 37, 145–149 (1986).

D. C. Agrarwal and R. Raj, Acta Metall. 37, 1265–1270 (1989).

V. C. Jobin, R. Raj, and S. L. Phoenix, Acta Metal Mater. 40, 2269–2280 (1992).

P. Hancock, J. R. Nicholls, and K. Mahmood, Corros. Sci. 35, 979–987 (1993).

M. M. Nagl, W. T. Evans, D. J. Hall, and S. R. J. Saunders, Oxid. Met. 42, 431–449 (1994).

R. E. Lobnig and H. J. Grabke, Corros. Sci. 30, 1045–1071 (1990).

R. Yashiro, J. Jpn. Soc. Heat Treat. 31, 205–211 (1991).

D. K. Footner, D. R. Holmes, and D. Mortimer, Nature (London) 216, 54–56 (1967).

P. Hancock and J. R. Nicholls, Mater. Sci. Technol. 4, 398–406 (1988).

J. K. Tien and J. M. Davidson, in Proceedings of the Symposium on Stress Effects and the Oxidation of Metals, J. V. Cathcart, ed. (AIME, 1974), pp. 200–219.

M. Schütze, Mater. Sci. Technol. 6, 32–38 (1990).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Sohn, I.R., Narita, T. Cracking Behavior of Cr2O3 Scales on Fe–25Cr Alloys Under Creep Deformation at 973 K in Ar Atmosphere. Oxidation of Metals 59, 333–352 (2003). https://doi.org/10.1023/A:1023096128605

Issue Date:

DOI: https://doi.org/10.1023/A:1023096128605