Abstract

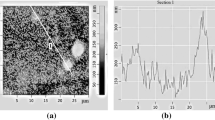

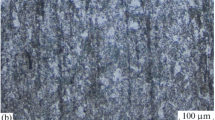

The mechanism and effect of magnetic-abrasive treatment (MAT) on the wear resistance of WC ― 8 Co hard alloy inserts have been studied. MAT was carried out on hard alloy inserts before and after coating deposition. The results of local x-ray and electron microscopic analyses are discussed. It has been established that a TiC coating deposited by CVD after MAT contains iron inclusions. The transition layer (coating-hard alloy base) is narrower as compared with the literature data and contains more iron than the coating and base. The mechanism of the MAT effect on the wear resistance of inserts with diffusion coatings is proposed. The effect of MAT of insert coatings on their wear resistance is discussed as well. The highest level of strengthening has been achieved by treatment using the following scheme: magnetic-abrasive treatment + chemical vapor deposition + magnetic abrasive treatment (MAT + CVD + MAT).

Similar content being viewed by others

REFERENCES

M. G. Loshak and L. I. Aleksandrova, Strengthening of Hard Alloys[in Russian], Nauk. Dumka, Kyiv (1977).

V. Ye. Oliker, Powders for Magnetic-Abrasive Treatment of Wear-Resistant Coatings[in Russian], Metallurgia, Moscow (1990).

V. D. Efremov and P. I. Yashcheritsin, Technological Support for High Quality Cutting Edges of Tools and Parts[in Russian], Navuka i Tekhnika, Minsk (1997).

V. F. Loskutov, V. G. Khizhnyak, Yu. K. Kunitskii, and M. V. Kindrachuk, Diffusion Carbide Coatings[in Russian], Tekhnika, Kyiv (1991).

T. Ya. Grydasova, A. F. Zhornyak, L. A. Karpova, et al., “Optimization of regimes of magnetic-abrasive treatment of hard alloys,” Poroshk. Metall.No. 4, 91–95 (1982).

A. S. Vereshchaka, “Cutting tools with wear-resistant coatings,” STIN, No. 9, 33–40 (2000).

I. A. Podchernyayeva, A. D. Panasyuk, et al., “Electrospark alloying of construction alloys of composite materials based on TiCN -?AlN,” Poroshk. Metall.Nos. 5-6, 21–29 (2000).

Pat. 2155243 (Russia), Method for Ion-Beam Treatment of Hard-Alloy Articles Publ. 27.08.00.

Pat. 5916383 (USA), Method of Short Peening a Hardened Metal Product with Shot Having High HardnessPubl. 29.06.99.

Research-based products to increase productivity, Sandvik Coromant Co Booth E-2604, Mod. Mach. Shop. 73 No. 3, 344–346 (2000).

Yu. M. Baron, Magnetic-Abrasive and Magnetic Treatment of Articles and Cutting Tools[in Russian], Mashinostroyeniye, St. Petersburg (1986).

F. Yu. Sakulevich and L. M. Kozhuro, Volume Magnetic-Abrasive Treatment[in Russian], Navuka i Tekhnika, Minsk (1978).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Stepanova, I.V. Effect of Magnetic-Abrasive Treatment on Wear Resistance of Hard Alloy Inserts with Diffusion Coatings Based on TiC. Powder Metallurgy and Metal Ceramics 41, 575–580 (2002). https://doi.org/10.1023/A:1022976001971

Issue Date:

DOI: https://doi.org/10.1023/A:1022976001971