Abstract

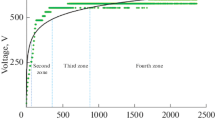

The effects of pulse periods and duty cycles on the current efficiency of acid copper plating in a wide range of pulse periods from 200 to 0.02 ms were studied. It was found the current efficiency decreased with shortening pulses in the millisecond range but increased with shortening pulses in the microsecond range. A mathematical model based on the concept of equivalent circuit was employed to simulate the potential responses. Shortening the pulse period was found to change the rate-determining step from charge transfer and surface diffusion to the first step charge transfer. In the millisecond range, the current efficiency decreases with shortening pulse period due to the disproportionation of cuprous ions and the dissolution of copper adatom. However, in the microsecond range, the current efficiency was found to increase with decreasing pulse period because the adatoms are directly incorporated into steps and kink sites, and the disproportionation of cuprous ions or the dissolution of copper adatoms has less chance to occur.

Similar content being viewed by others

References

J.M. Quemper, E.D. Gergam, N.F. Rodriquez, J.P. Gilles, J.P. Grandchamp and A. Bosseboeuf, J. Micromech. Microeng. 10 (2000) 116.

N.S. Qu, K.C. Chan and D. Zhu, Surf. Coat. Technol. 91 (1997)220.

J.J. Kelly, P.E. Bradley and D. Landolt, J. Electrochem. Soc. 147 (2000) 2975.

E.T. Taylor, J.J Sun and M.E. Inman, Plat. Surf. Finish. 87 (2000)68.

C. Lingk and M.E. Gross, J. Appl. Phys. 84 (1998) 5547.

H.Y. Cheh, J. Electrochem. Soc. 118 (1971) 1132.

K. Viswanathan and H.Y. Cheh, J. Electrochem. Soc. 126 (1979)398.

D-T. Chin, J. Electrochem. Soc. 135 (1983) 1657.

A.C. West, C.C. Cheng and B.C. Baker, J. Electrochem. Soc. 145 (1998) 3070.

C.C. Wan, H.Y. Cheh and H.B. Linford, Plat. Surf. Finish. 63 (1977) 66.

C.C. Wan, H.Y. Cheh and H.B. Linford, J. Appl. Electrochem. 9 (1979) 29.

C.J. Chen and C.C. Wan, J. Electrochem. Soc. 136 (1989) 2850.

T.A. Eckler, B.A. Manty and P.L. Mcdaniel, Plat. Surf. Finish. 66 (1980) 60.

S. Yoshimura, S. Chida and E. Sato, Met. Finish. 84 (1986) 66.

K. Hosokawa, H. Angerer, J.Cl. Puippe and N. Ibl, Plat. Surf.Finish. 66 (1980) 52.

W.S. Miu and Y.S. Fung, Plat. Surf. Finish. 73 (1986) 66.

J. Cl. Puippe and N. Ibl, J. Appl. Electrochem. 10 (1980) 775.

W.C. Tsai, C.C. Wan and Y.Y. Wang, J. Electrochem. Soc. 149 (2002) C229.

E. Mattsson and J.O'M. Bockris, Trans. Farad. Soc. 55 (1959) 1586.

J.O'M. Bockris and H. Kita, J. Electrochem. Soc. 109 (1962) 928.

O.R. Brown and H.R. Thirsk, Electrochimi. Acta 10 (1965) 383.

G.W. Tindall and S. Bruckenstein, Anal. Chem. 40 (1968) 1051.

W.J. Lorenz, H.D. Hermann, N. Wu¨ thrich and F. Hilbert, J.Electrochem. Soc. 121 (1974) 1167.

J.R. White, J. Appl. Electrochem. 17 (1987) 977.

E. Gileadi and V. Tsionsky, J. Electrochem. Soc. 147 (2000) 567.

J.D. Reid and A.P. David, J. Electrochem. Soc. 134 (1987) 1389.

M. Paunovic and M. Schlesinger, ‘Fundamentals ofElectroche mical Deposition’ (John Wiley & Sons, New York, 1998), p. 103.

J.J. Kelly and A.C. West, J. Electrochem. Soc. 145 (1998) 3477.

J.O'M. Bockris and B.E. Conway, J. Chem. Phys. 28 (1958) 707.

N. Tantavichet and M.D. Pritzker, J. Electrochem. Soc. 149 (2002) C289.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tsai, WC., Wan, CC. & Wang, YY. Mechanism of copper electrodeposition by pulse current and its relation to current efficiency. Journal of Applied Electrochemistry 32, 1371–1378 (2002). https://doi.org/10.1023/A:1022649314480

Issue Date:

DOI: https://doi.org/10.1023/A:1022649314480