Abstract

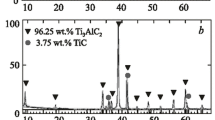

The influence of changes in the nominal composition and preparation conditions on the formation of Tl(1223) under a high isostatic gas pressure was studied. Optimization of the cation substitution allowed to increase the phase purity, whereas substitution of small amounts of oxygen by fluorine decreased the formation temperature of the Tl(1223) phase and extended the temperature range favorable for grain growth. A two-step reaction involving substantial melting produced well shaped, plate-like grains.

Similar content being viewed by others

REFERENCES

R.E. Gladyshevskii, A. Perin, B. Hensel, R. Flükiger, R. Abraham, K. Lebbou, M.Th. Cohen-Adad, and J.-L. Jorda, Physica C 255, 113 (1995).

R.E. Gladyshevskii, Ph. Galez, K. Lebbou, J. Allemand, R. Abraham, M. Couach, R. Flükiger, J.-L. Jorda, and M.Th. Cohen-Adad, Physica C 267, 93 (1996).

M. Al-Mamouri, P.P. Edwards, C. Greaves, and M. Slaski, Nature 369, 382 (1994).

R.E. Gladyshevskii, E. Bellingeri, M. Dhallé, and R. Flükiger, Proceedings of SPA '97, accepted.

E. Bellingeri, R.E. Gladyshevskii, and R. Flükiger, J. Supercond., this issue.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Gladyshevskii, R.E., Bellingeri, E., Marti, F. et al. Preparation of High - Purity Tl(1223) Ceramics. Journal of Superconductivity 11, 109–110 (1998). https://doi.org/10.1023/A:1022614820033

Published:

Issue Date:

DOI: https://doi.org/10.1023/A:1022614820033