Abstract

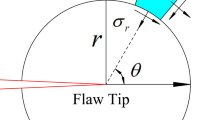

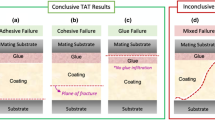

The precracking requirements for fracture toughness testing of metallic materials are investigated in this study. In addition, some experiments were performed in the transition region to quantify the consequences of violating these requirements. It is found that the different standards are not consistent. For most of the requirements some rationale can be found. Some theoretical developments were performed to justify the use of a fixed maximum stress intensity factor. This limit is tightly related to the fracture mechanism and to the fracture process zone. From an experimental point of view, a relatively limited effect of precracking on the fracture toughness is found.

Similar content being viewed by others

References

Anderson, T.L., Stienstra, D. and Dodds, R.J. Jr. (1994). A theoretical framework for addressing fracture in the ductile-brittle transition region, Fracture Mechanics: Twenty-Fourth Volume, ASTM STP 1207, John D. Landes, Donald E. McCabe and J.A.M. Boulet, Eds., American Society for Testing and Materials, Philadelphia, 186–214.

Brown, W.F. Jr. and Srawley J.E. (1966). Plane Strain Crack Toughness Testing of High Strength Metallic Materials. ASTM STP 410, 46–51.

Dahl, W., Kretzschmann W.-B. (1977) Influence of precracking and grain size on fracture toughness of structural steels. ICF4, Vol. 2, Waterloo, Canada, 17–21.

Gardiner, R.W. (1983) Effects of fatigue precracking stress intensity factor on the measured fracture toughness of titanium alloy imi 550. Proceedings of The metallurgy of light alloys, 245–251.

Heerens, J., Read, D.T., Cornec, A., Schwalbe, K.-H. (1991). Interpretation of fracture toughness on the ductile-to-brittle transition region by fractographical observations. Mechanical Engineering Publications, 659–678.

Hsing-Shih, C., Ji-Liang, D. (1983). Influence of precracking load on critical stress intensity factor of mild steel, Journal of Materials Science 18, 2305–2310.

Kaufman, J.G., Schilling, P.E. (1973). Influence of Stress Intensity Level During Fatigue Precracking on Results of Plane-Strain Fracture Toughness. Progress in Flaw Growth and Fracture Toughness Testing, ASTM STP 536, 312–319.

Lucon, E., Scibetta, M., Chaoudi, R., and van Walle, E. (2002). Fracture Toughness Measurements in the Transition Region Using Sub-Size Precracked Charpy and Cylindrical Bar Specimens. Small Specimen Test Techniques: Fourth Volume, ASTM STP 1418, M.A. Sokolov, J.D. Landes, and G.E. Lucas, Eds., American society for Testing and Materials, West Conshohocken, PA.

May, M.J. (1970). British experience with plane strain fracture toughness (KIc) testing. Review of Developments in Plane Strain Fracture Toughness Testing, ASTM STP 463, 41–62.

McMeeking, R.M. and Parks, D.M. (1979). On Criteria for J-Dominance of Crack-Tip Fields In Large-Scale Yielding, ASTM STP 668, American Society for Testing and Materials, Philadelphia, 175–194.

Miller, A.G. (1988). Review of limit loads of structures containing defects, Int. J. Pres. Ves. and Piping 32, 197–327.

Pesek, L., Veles, P. and Kovac, L. (1980) The influence of load at fatigue precracking on fracture toughness test results, Kovove materialy 6, 18, Bratislava (in slovak)

Ogata, T. et al. (1988) Effect of specimen size, side-grooving, and precracking temperature on J-integral test results for AISI 316LN at 4K. Advances in cryogenic engineering 34, proceedings of the conf., 259–266.

Pickles, B.W. and Cowan, A. (1983). A review of warm prestressing studies, Int. J. Pres. Ves. and Piping 14, 95–131.

Scibetta, M., Lucon, E., and van Walle, E. (2002). Technical Appendix of ‘Towards a uniform precracking procedure for fracture toughness testing’, report BLG-904, SCK·CEN Mol, Belgium.

Tobler, R.L. and Shimada, M. (1991).Warm precracking at 295 K and its effects on the 4-K toughness of austenitic steels, J. Test. Eval. 19, No 4, 312–320.

Wallin, K. (1991). Statistical modelling of fracture in the ductile-to-brittle transition region, Defect assessment in Components-Fundamentals and Applications, ESIS/EGF9 (Ed. by Blauel J.G. and Schwalbe K.-H.) Mechanical Engineering Publications, London, 415–445.

Wallin, K. (1998). Master curve analysis of ductile to brittle transition region fracture toughness round robin data. The ‘EURO’ fracture toughness curve. VTT Publications: 367, Espoo, 1–58.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Scibetta, M., Lucon, E., van Walle, E. et al. Towards a uniform precracking procedure for fracture toughness testing. International Journal of Fracture 117, 287–296 (2002). https://doi.org/10.1023/A:1022072320277

Issue Date:

DOI: https://doi.org/10.1023/A:1022072320277