Abstract

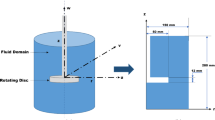

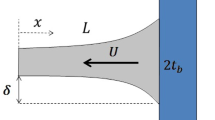

The ability of a lubricant to protect increasingly complex diesel engines directly affects engine durability and warranty costs and is becoming increasingly costly to validate. This paper presents a novel approach combining a chemical kinetic model using rate constants determined by a set of laboratory bench tests and a finite-difference computer program to predict lubricant performance in a given diesel engine. The computer program takes into account the engine's mechanical design, such as temperature, pressure, oil flow rate, top ring zone volume, and other parameters. The chemical kinetic model incorporates the kinetic rate constants determined for that particular lubricant in a set of special bench-test procedures tailored to a particular engine and its operating conditions. The bench-test procedures take into account the necessary environment in that particular engine such as specific metal catalysis, oxidation conditions, and deposit formation. The computer program then combines the lubricant degradation model with the engine operating sequence to yield a predictive simulation. This approach is capable of predicting the amount of deposit in the top ring groove and the amount of oil consumption in that engine. The computer program models the engine as three chemical reactors in series. The three reactors are: the oil sump, the top piston ring groove, and the piston cylinder-liner interface. Oil flows from the sump to the piston rings and to the piston liner area. The oxidation process is described by a set of simplified chemical kinetic rate equations. The kinetic constants of the lubricant are determined by laboratory bench-test procedures using Differential Scanning Calorimetry (DSC), a Thermal Gravimetric Analyzer (TGA), and the Micro-Oxidation test apparatus. The design and the operating conditions of the engine define the chemical reaction conditions used in the simulation program such as the temperatures of the reactions, the residence time in a particular reactor, the volume of the reactors, and the operating sequence of the engine. The simulation program is validated by the Caterpillar 1K engine dynamometer test results. Two experimental high-temperature lubricants and three IK reference oils were used in this study. Good agreement between model simulation and 1K engine test results was obtained.

Similar content being viewed by others

References

M. F. Fox, C. J. Jones, D. Hickford, D. J. Picken, F. Kelley and D. E. Copp, Proceedings of Annual Automotive Technology Development Contractors Coordinating Meeting, Dearborn, Michigan, Oct. 24–27, 1994, SAE SP-289, published by SAE, ISBN 1-56091-654-0, 1995.

S. K. Naidu, E. E. Klaus and J. L. Duda, Ind. Eng. Chem. Prod. Res. Dev. 25 (1986) 596-603.

S. M. Hsu, C. S. Ku and P. T. Pei, in Aspects of Lubricant Oxidation ASTM STP 916, eds W. H. Stadtmiller and A. M. Smith (American Society for Testing and Materials, Philadelphia, 1986) p. 27.

F. E. Lockwood, E. E. Klaus and J. L. Duda, ASLE Trans., 24(2) (1981) 276-284.

S. M. Hsu, NBS SP 584, proc. Joint Conf. On Measurements and Standards for Recycled Oil/Systems Performance and Durability (1980) 191.

Y. Zhang, P. Pei, J. M. Perez and S. M. Hsu, Lubr. Eng. 48, 3, (1992) 189-195.

S. M. Hsu and A. L. Cummings, SAE paper #831682 in SAE SP 558 “Lubricant and Additive Effects on Engine Wear” 51 (1983).

J. M. Perez, P. Pei, Y. Zhang and S. M. Hsu, SAE Technical paper #910750, presented at the International Congress and Exposition, Detroit, MI, Feb. 25-March 1, 1991 (Society of Automotive Engineers, Warrendale, PA, 1991).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Chen, CI., Hsu, S.M. A Chemical Kinetics Model to Predict Lubricant Performance in a Diesel Engine. Part I: Simulation Methodology. Tribology Letters 14, 83–90 (2003). https://doi.org/10.1023/A:1021748002697

Issue Date:

DOI: https://doi.org/10.1023/A:1021748002697