Abstract

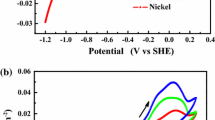

Sulfite may be added to copper cyanide solutions to reduce cyanide oxidation at the anode during copper electrowinning. Anodic sulfite oxidation is enhanced in the presence of copper cyanide. Sulfite also suppresses the oxidation of copper cyanide. The effect of sulfite on the oxidation of copper cyanide decreases with increasing mole ratio of cyanide to copper. This is related to the shift in the discharged species from Cu(CN)3 2− to Cu(CN)4 3− with increasing mole ratio of cyanide to copper. Sulfite is oxidized to sulfate. At [Cu+] = around 1 M, CN:Cu = 3.0–3.2, [OH−] = 0.05–0.25 M, [SO3 2−] = 0.4–0.6 M and the temperature = 50–60 °C, the anodic current efficiency of sulfite reached 80–90%. With further increase in sulfite concentration beyond 0.6 M, the current efficiency of sulfite oxidation will not be increased significantly. Further increase in CN:Cu mole ratio will result in decrease in the anodic current efficiency.

Similar content being viewed by others

References

J.S. Scott, The Proceedings of Gold Mining Effluent Treatment Seminars, Vancouver, BC (1989), p. 1.

N.L. Piret and H.J. Schippers, Extraction Metallurgy'89 (Institution of Mining and Metallurgy, London, 1989), p. 1041.

H. Soto, F. Nava and J. Jara, in D.M. Hausen (Ed.), ‘Global Exploration of Heap Leachable Gold Deposits’ (TMS, 1997), pp. 151–160.

E.L. Coltrinari, US Patent 4 708 804 (24 Nov. 1987).

G.W. Lower, US Patent 3 463 710 (26 Aug. 1969).

ECO Corporation Report, ‘ECO-Metal Cyanide Recovery System'.

Orocon Inc. Technology Report, ‘CELEC Cyanide Regeneration System'.

HSA Reactors Ltd, Technology Report, ‘Copper Recovery/Cyanide Regeneration'.

D.G. Dickson, US Patent 4 911 804 (1 Feb. 1988).

C.A. Fleming, W.G. Grot and J.A. Thorpe, ‘Hydrometallurgical Extraction Process', US Patent, 5 411 575 (2 May 1995).

G.R. Maxwell, J.A. Thorpe, K.M. Schall and K.A. Brunk, in D.M. Hausen (Ed.), op. cit. [3], pp. 141–149.

D.B. Dreisinger. J. Ji, B. Wassink and J. King, The Proceedings of Randol Gold Forum., Perth’ 95 (1995), pp. 239–244.

D.B. Dreisinger and J. Lu, unpublished results (1997).

J. Lu, D.B. Dreisinger and W.C. Cooper, J. Appl. Electrochem. 29 (1999) 1161.

J. Lu, D.B. Dreisinger and W.C. Cooper, Anodic oxidation of copper cyanide on graphite anode in alkaline solutions, J. Appl.Electrochem., in press.

J. Lu, D.B. Dreisinger and W.C. Cooper, Thermodynamics of aqueous copper cyanide system, Hydrometallurgy, in press.

J.M. Lancaster and R.S. Murray, J. Chem. Soc. A (1971) 2755.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lu, J., Dreisinger, D. & Cooper, W. Anodic behaviour of alkaline solutions containing copper cyanide and sulfite on the graphite anode. Journal of Applied Electrochemistry 32, 1109–1118 (2002). https://doi.org/10.1023/A:1021283501563

Issue Date:

DOI: https://doi.org/10.1023/A:1021283501563