Abstract

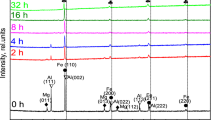

High-energy ball milling was used to promote the solubilization of iron into NiAl powder for an iron concentration range of 10–30 wt.%. The microstructural evolution induced by the intense mechanical deformations, under different milling conditions, was followed by X-ray diffraction and Mössbauer spectroscopy. The Mössbauer spectra are dominated by a magnetic sextet of about 33 T. Increasing the time and the speed of milling gives rise to a non-resolved doublet, having parameters typical of a NiAl compound with Fe atoms in solution. At the same time a reduction of lattice parameter occurs, which can be correlated to composition variations and partial disordering of the NiAl structure. Subsequent annealing modifies the Mössbauer spectra noticeably. In particular, the non-magnetic component becomes a broad singlet. Both diffraction analysis and Mössbauer spectroscopy indicate that a fcc Ni(Al,Fe) solid solution is forming in samples milled in agate. It is observed that the grain size of the milled products remains in the nanometric range even after thermal treatment, which adds interest to possible applications.

Similar content being viewed by others

References

Miracle, D. B., Acta Metall. Mater. 41 (1993), 694.

Darolia, R., J. Metals 43 (1991), 44.

Noebe, R. D., Bowman, R. R. and Nathal, M. V., In: N. S. Stoloff and V. K. Sikka (eds), Physical Metallurgy and Processing of Intermetallic Compounds, Chapman &; Hall Editions, London, 1996, p. 212.

Hishida, K., Kainuma, R., Ueno, N. and Nishizawa, T., Metall. Trans. 22A (1991), 441.

Liu, Z. G., Guo, J. T., Zhou, L. Z., Hu, Z. Q. and Unemoto, M., J. Mater. Sci. 32 (1997), 4857.

Lutterotti, L., Matthies, S. and Wenk, H. R., Int. Union of Crystallography (IUCr) Newsletter 21 (1999), 14.

Gialanella, S., Guella, M., Baro, M. D., Malagelada, J. and Suriñac, S., In: J. J. deBarbadillo, F. H. Froes and R. Schwarz (eds), Proc. 2nd Int. Conf. on Structural Applications of Mechanical Alloying, Vancouver, ASM Int., Materials Park, OH, USA, 1993, p. 321.

Kogachi, M., Minamigawa, S. and Nakahigashi, K., Acta Metall. Mater. 40 (1992), 1113.

Ron, M. and Mathalone, Z., Phys. Rev. B 4 (1971), 774.

Gielen, P. M. and Kaplow, R., Acta Metall. 15 (1967), 49.

Bogner, J., Steiner, W., Reissner, M., Mohn, P., Blaha, P., Schwarz, K., Krechler, R., Ipser, H.and Sepiol, B., Phys. Rev. B 58 (1998), 14 922.

Nasu, S., Gonser, U. and Preston, R. S., J. Phys. Colloque C 1 (1980), C1-385.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Principi, G., Spataru, T., Maddalena, A. et al. High-Energy Ball Milling of NiAl(Fe) System. Hyperfine Interactions 139, 315–324 (2002). https://doi.org/10.1023/A:1021281619242

Issue Date:

DOI: https://doi.org/10.1023/A:1021281619242