Abstract

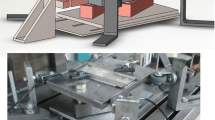

This study has successfully incorporated Al2O3, SiC particulates into the 7005Al alloy matrix by using a drag-push method. The reinforced particulates are uniformly distributed in the matrix. This study also discusses the influence of aging treatment on the friction welding properties of 7005Al/10 wt%, 15 μm and 6 μm SiC(p) composites and 7005Al/10 wt%, 15 μm Al2O3(p) composites joint system. Experimental results show that after peak aging treatment was performed, if SiC particulates were used in the strengthening phase, the heat-affected zone (HAZ) had higher density of strengthening particulate, this resulted an increase in the hardness and stress concentration at the fully plasticized zone (Zpl) of the HAZ region, but a decrease in the width of the Zpl zone and the welding strength. And the welded fracture surface morphology had a low-ductile fracture.

Similar content being viewed by others

References

K. K. WANG and P. NAGAPPAN, Welding Journal Research Supplement 49 (1970) 419.

K. K. WANG and WEN. LIN, ibid. 53 (1974) 233.

D. E. SPINDLER, Welding Journal 73 (1994) 27.

S. BEKIR YILBAS and Z. AHMET SAHIN, Materials Processing Technology 54 (1995) 76.

M. B. D. ELLIS, M. E. GITTOS and P. P. I. THREADGILL, Materials World 12 (1994) 415.

K. K. CHAWLA, A. H. ESMAEILI, A. K. DATYE and A. K. VASUDEVAN, Scripta Metall. Mater 25 (1991) 1315.

S. SURESH, T. CHRISTMAN and Y. SUGIMURA, ibid. 23 (1989) 1599.

J. LLORCA, A. NEEDLEMAN and S. SURESH, Acta Metall. Mater. 39 (1991) 2317.

G. J. MAHON, J. M. HOWE and A. K. VASUDEVAN, ibid. 38 (1990) 1503.

J. J. LEWANDOWSKI, C. LIU and W. HUNT, Mater. Sci. Engin. A 107 (1989) 241.

L. E. MURR, G. LIN and J. C. MC CLURE, J. Mater. Sci. 33 (1998) 1243.

M. W. MAHONEY, C. G. RHODES, J. G. FLINTOFF, R. A. SPURLING and C. C. BAMPTON, Scripta Mater. 36 (1997) 69.

J. E. HATCH, in“Aluminum Properties and Physical Metallurgy” 1st ed. (American Society for Metals, Metals Peak, Ohio, 1984) p. 185.

O. T. MIDLING and O. GRONG, Acta Metal. 42 (1994) 1611.

M. B. HOLLANDER, Met. Eagng Q 2 (1962) 14.

Y. B. BRECHET, J. NEWELL, S. TAO and J. D. EMBURRY, Scripta Metallurgica et Materialia. 28 (1993) 47.

C. B. LIN, C. K. MU, W. W. WU and C. H. HUNG, Welding Journal (1999) 100.

R. J. ARSENAULT and N. SHI MAT, Material Science and Engineering 81 (1986) 175.

J. K. SHANG and R. O. RITCHIE, Acta Metallurgica. 37 (1989) 2267.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lin, C.B., Chou, IC. & Ma, C.L. Manufacturing and friction welding properties of particulate reinforced 7005 Al. Journal of Materials Science 37, 4645–4652 (2002). https://doi.org/10.1023/A:1020664803115

Issue Date:

DOI: https://doi.org/10.1023/A:1020664803115