Abstract

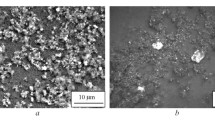

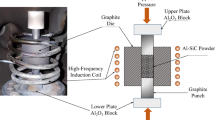

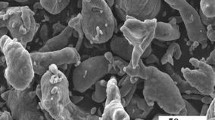

Mechanical alloying has come to the fore in fields such as the production of intermetallic compounds, supersaturated solid solutions, amorphous materials and metal matrix composites. With this process, composite powders are obtained with characteristics that are impossible to achieve employing conventional powder metallurgy techniques. In this work, aluminium powder AA6061 is mixed with silicon and aluminium nitrides in a conventional mixer and in a high-energy ball mill to obtain composite powders that are subsequently uniaxially cold pressed and hot extruded. The necessary pressure to extrude the composite cold pressed powders varies with the powder condition, being lower for the composite powder conventionally mixed, higher for the composite powder after a short time of milling, and intermediate after a longer time of milling, due to the morphological and structural changes typical of the mechanical alloying process.

Similar content being viewed by others

References

J. S. BENJAMIN, Metall. Trans. 1 (1970) 2943.

A. BOSE, “Advances in Particulate Materials” (Butterworth-Heinemann, Newton, MA, 1995).

L. LU and M. LAI, “Mechanical Alloying, ” edited by Kluwer Academic Plublishers, 1998.

Y. B. LIU, S. C. LIM, L. LU and M. O. LAI, J. Mater. Sci. 29 (1994) 1999.

C. SURYANARAYANA, Progress in Materials Science 46 (2001) 1.

C. E. COSTA, W. C. ZAPATA, J. M. TORRALBA, J. M. RUIZ PRIETO and V. AMIGÓ, Mat. Sci. Forum 217 (1996) 1859.

J. S. BENJAMIN and T. E. VOLIN, Met. Trans. 5 (1974) 1929.

J. S. BENJAMIN, Modern Developments in Powder Metallurgy 21 (1988) 397.

B. J. M. AIKIN and T. H. COURTNEY, Met. Trans. A 24 (1992) 647.

G. B. SCHAFFER, T. B. SERCOMBE and R. N. LUMBEY, Mater. Chem. Phys. 67 (2001) 85.

M. J. TAN and X. ZHANG, Mat. Sci. Eng. A 244 (1998) 80.

R. SANKAR and P. SINGH, Mat. Letters 36 (1998) 201.

L. LU, M. O. LAI and C. W. NG, Mat. Sci. Eng. A 252 (1998) 203.

P. R. ROBERTS and B. L. FERGUSON, International Materials Reviews 36(2) (1991) 62.

S. KALPAKJIAN, Manufacturing Process for Engineering Materials, World Student Series Edition, Addison-Wesley Publishing Company, Inc., p. 634.

M. LIEBLICH, G. CARUANA, M. TORRALBA and H. JONES, Powder Metall. 39(2) (1996) 143.

J. B. FOGAGNOLO, E. M. RUIZ-NAVAS, M. H. ROBERT and J. M. TORRALBA, Mat. Sci. Eng. A, submitted for publication in Mat. Sci. Eng. A.

J. ZHOU, PhD Thesis from Delft University of Technology, Holland, 1991.

J. B. FOGAGNOLO, F. J. VELASCO, M. H. ROBERT and J. M. TORRALBA, accepted for publication in Mat. Sci. Eng. A.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Fogagnolo, J.B., Robert, M.H., Ruiz-navas, E.M. et al. Extrusion of mechanically milled composite powders. Journal of Materials Science 37, 4603–4607 (2002). https://doi.org/10.1023/A:1020648316319

Issue Date:

DOI: https://doi.org/10.1023/A:1020648316319