Abstract

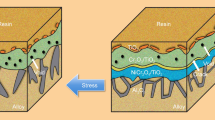

Thermal–barrier coatings (TBCs) consist of a magnetron-sputtered Ni–30Cr–12Al–0.3Y (wt.%) bond coat to protect the substrate superalloy from oxidation/hot corrosion and an electron-beam physical-vapor deposited (EB–PVD) 7 wt.% yttria partially stabilized zirconia (YPSZ) top coat. The thermal cyclic life of the TBC system was assessed by furnace cycling at 1050°C. The oxidation kinetics were evaluated by thermogravimetric analysis (TGA) at 900, 1000, and 1100°C for up to 100 hr. The results showed that the weight gain of the specimens at 1100°C was the smallest in the initial 20 hr, and the oxide scale formed on the sputtered Ni–Cr–Al–Y bond coat is only Al2O3 at the early stage of oxidation. With aluminum depletion in the bond coat, NiO, Ni(Cr,Al)2O4, and other spinel formed near the bond coat. During thermal cycling, microcracks were initiated preferentially in the YPSZ top coat along columnar grain boundaries and then extended through and along the top coat. The growth stress of TGO added to the thermal stress imposed by cycling, lead to the separation at the bond coat–TGO interface. The ceramic top coat spalled with the oxide scale still adhering to the YPSZ after specimens had been cycled at 1050°C for 300 cycles. The failure mode of the EB–PVD ZrO2–7 wt.% Y2O3 sputtered Ni–Cr–Al–Y thermal-barrier coating was spallation at the bond coat–TGO interface.

Similar content being viewed by others

REFERENCES

R. A. Miller, Surf. Coat. Technol. 30, 1 (1987).

M. Hull, Surf. Eng. 13, 456 (1997).

T. N. Rhys-Jones and F. C. Toriz, High Temp. Technol. 7, 73 (1989).

X. Bi, X. Hu, and S. Gong, Surf. Coat. Technol. 130, 122 (2000).

N. Czech, H. Fietzek, M. Juez-Lorenzo, V. Kolarik, and W. Stamm, Surf. Coat. Technol. 113, 157 (1999).

H. Lou, F. Wang, B. Xia, and L. Zhang, Oxid. Met. 38(3/4), 299 (1992).

F. Wang, Oxid. Met. 48, 215 (1997).

M. Li, Z. Zhang, X. Sun, H. Wu, and H. Guan, J. Chinese Soc. Corros. Protection 22, 153 (2002).

H. J. Grabke, M. W. Brumm, and B. Wagemann, Mater. Corros. 47, 675 (1996).

W. L. Worrell, in Topics in Applied Physics, Vol. 21, S. Geller, ed. (Springer-Verlag, New York, 1977), p. 143.

N. Birks and G. H. Meier, Introduction to High Temperature Oxidation of Metals (Edward Arnold, London, 1983), p. 161.

K. P. R. Reddy, J. L. Smialek, and A. R. Cooper, Oxid. Met. 30, 429 (1982).

M. Li, X. Sun, Z. Zhang, S. Gong, W. Hu, H. Guan, and Z. Hu, Acta Metall. Sinica 38(1), 79 (2002).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Li, M.H., Zhang, Z.Y., Sun, X.F. et al. Oxidation and Degradation of EB–PVD Thermal–Barrier Coatings. Oxidation of Metals 58, 499–512 (2002). https://doi.org/10.1023/A:1020573006218

Issue Date:

DOI: https://doi.org/10.1023/A:1020573006218